** For a 10% off discount code, please listen to the podcast. **

You won’t hear this discount code in the video!

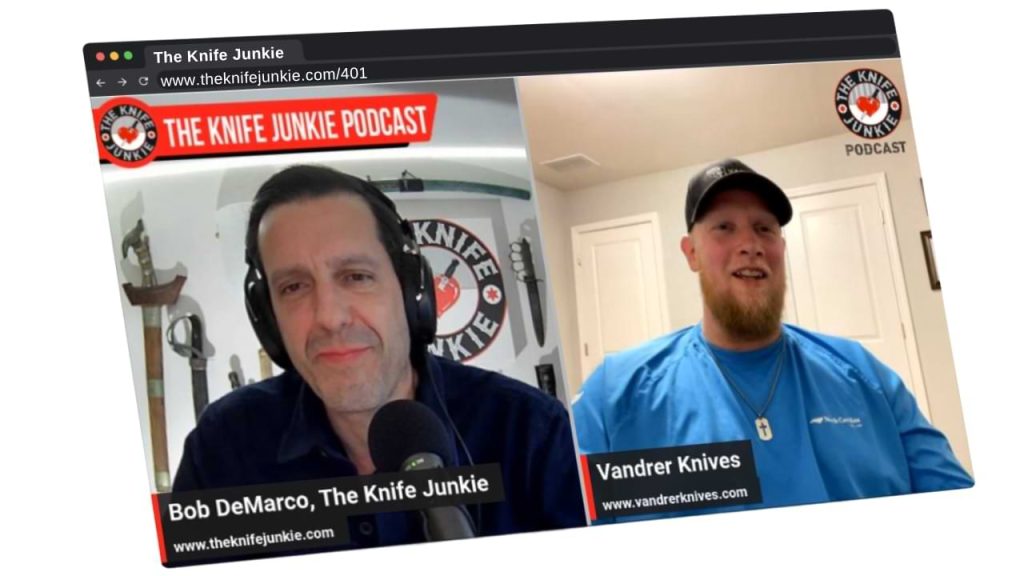

Vandrer Knives – The Knife Junkie Podcast (Episode 401)

Ethan Curtis of Vandrer Knives joins Bob “The Knife Junkie” DeMarco on Episode 401 of The Knife Junkie Podcast. Ethan originally started making knives as a hobby in 2019 while working as a Bail Bondsman and Bail Enforcement agent in North Carolina.

Ethan has called his wife Chrissy a nomad for many years due to her constant desire to move all over the country. The name Vandrer (Norwegian for wanderer) is a tribute to her and the vikings from whom his design inspiration comes.

The Vandrer logo incorporates Odin and a Viking coming together in a “V” and Vandrer’s mission is to create quality tools at an affordable price that are ready for any task. Vandrer seeks to ensure that as technology, fighting styles and knife uses change the company remains ready to adapt to those new developments.

Find Vandrer Knives online at www.vandrerknives.com and on Instagram at instagram.com/vandrerknives.

Be sure to support The Knife Junkie and get in on the perks of being a Patron — including early access to the podcast and exclusive bonus content. You also can support the Knife Junkie channel with your next knife purchase. Find our affiliate links at theknifejunkie.com/knives.

Ethan Curtis of Vandrer Knives, a former Bail Bondsman and Bail Enforcement agent, is this week's guest on #theknifejunkie #podcast (Episode 401). Cool guy and some cool knives. Share on XEthan Curtis, Vandrer Knives - The Knife Junkie Podcast (Episode 401)

©2023, Bob Demarco

The Knife Junkie Podcast

https://theknifejunkie.com

Transcript

[0:00] Welcome to the Knife Junkie podcast, your weekly dose of knife news and information about knives and knife collecting.

Here's your host, Bob the Knife Junkie DeMarco. Welcome to the Knife Junkie podcast.

I'm Bob DeMarco.

On this edition of the show, I'm speaking with Ethan Curtis of Vandrer Knives.

Ethan's work first caught my eye on Instagram, where his handmade fixed blade knives struck me as equal parts self-defense and utility, with a look that harkens back to old Northern Europe.

Since I first started paying attention to Ethan's knives, they've progressed from cool, rugged looking tools to beautiful and refined knives.

[0:46] And in that time, I've watched his range in terms of design grow, with some models seeming universally purpose purpose driven and others utilitarian, but you know how I love the purpose driven. What's more, I've gotten a hint of Ethan's inspiration and personal background, and can't wait to hear how he's used that to build a career in knives. But first, like, comment, subscribe and share this show. Also, you can download it to your favorite podcast app. As always, you can check out our Patreon account on Patreon and help support the show. quickest way to do that is is to go over to theknifejunkie.com. Again, that's theknifejunkie.com.

Do you use terms like handle-to-blade ratio, walk-and-talk, hair-popping sharp, or tank-like?

Then you are a dork and a knife junkie. Just a quick note before we get into this interview with Ethan Curtis of Vandrer Knives.

[1:44] He got in touch with me after we recorded and he wanted to offer you all a 10% discount, of you who are listening to this podcast on the wonderful Vandrer knives and you will see what we're talking about shortly. Just go to his website when you're ordering a knife and put in the discount code, theknifejunkie10. Again, that's theknifejunkieten for 10% off a purchase of a Vandrer knife.

You're listening to the Knife Junkie Podcast. Ethan, welcome to the show.

Hey, thanks for having me on, Bob.

It's my pleasure. I realized as I was reading my intro that I botched the name and then once I realized that it threw me off. It's Vandrer Knives, right?

Yeah, Vandrer Knives.

Alright, so let's start right there. What does Vandrer mean?

It means wonder in Norwegian. So that's a story, that name is a story in itself.

Well, okay. Well, let's start right there. What is the story behind Vandrer, the name?

So I actually started this company early 2020. I didn't know much about knives, so I started it with my dad and my brother.

Was doing more, we actually used to be named Northern Braid Knives.

[3:03] And that was our original name. Well, our plan was to run it together.

And me and my brother just have so, our styles are so different that, you know, we just kind of want to do our own thing.

And if you check him out, you'll see that we're kind of worlds apart on how we do and design things.

And so we wanted to come up with a cool name. Most of our knives started, we started with a sax and a wharncliffe.

So we wanted to stick with that Viking style theme.

And my wife is a nomad.

I mean, we've moved all over. I've lived in North Carolina, Georgia.

We met in Tennessee. We've lived in Alaska, which is really where our company took off.

And so I wanted to come up with something along those lines.

So we named it Banner and Ives, basically Wanderer and Ives.

And yeah, that's just kind of us. You know, my wife would move every five months if she could.

And so, uh, I just devoted this company to her and cause she's really been the supportive piece behind it.

So I had to give her a little piece in there, you know, of course, the power behind the power behind the throne, as they say.

But what, uh, so all those places, uh, many of them in the south, but Alaska, that's a, that's a, a, uh, uh, that's a different one thrown in there of all those places that you've wandered, what did you find the most inspirational for your knife.

[4:33] So, Alaska is really the crux of where we are. In fact, if you look on my page, we still claim that because that's where I really found my style and identity.

It's where most of my growth came from. And really, I was out in the wilderness a lot more up there than down here.

I mean, I don't even have trees in my backyard here. So it's a little bit different.

But that's, Alaska is really the place that built us and it's really where we started.

And so I attribute a lot of where I'm at right now to Alaska, which is why you'll still see that on my page.

I don't plan on taking that down anytime soon. Where in Alaska were you?

We lived in Wasilla. It's about an hour north of Anchorage.

[5:18] Okay, so my mom and my sister went to Alaska on a mother-daughter trip about 10 years ago at this point.

And I just remember burning with jealousy. And I was like, well, I know I'm not a daughter, so I can't go on this trip.

But Alaska, I've always wanted to go up there, and I haven't been there yet.

What about Alaska? What about it up there is such a draw to so many people?

I mean, it is what it says it is, the last frontier. I mean, there's wilderness everywhere.

And the cool part for us was, it's really like its own world.

I mean, you get up there and you're driving down the road and then you've got four wheelers driving on the side.

They have their own road and then a pedestrian road up there on the other side.

And so you kind of get used to seeing snow machines and four wheelers all time of year.

And it's the coolest part about it was the animals, no doubt.

I mean, we were sitting in our living room and a moose came up and just put its nose on our glass.

And, you know, there's been several times we had to get our dogs back because the moose would come out and charge at us. So it's like living in the wild, wild west, except, you know.

[6:32] Five times bigger than every other state in America.

Well, to those of us, yeah, I'm a Yank. I grew up outside of Cleveland. And I've lived near or in major metropolitan places basically my whole life.

I always imagined a moose to be like a deer, just shaped differently, but that's not the case.

[6:53] No, they're about three or four times the size of moose. My first experience was we pulled up in my parents' house up there, and a moose was by my dad's Dodge 2500, and the back was as tall as the top of the truck.

When you grow up around white-tailed deer like I did, seeing a moose is a completely different world.

It's really cool. The cool thing about it was we had mountains all around us and we'd just go hiking, especially in the summer because you don't have any dark.

You get about three hours of darkness and you can hike till midnight if you want.

It's definitely its own experience for sure. So that's where you kind of had your coming of age as a knife maker.

That's, I guess, where you really began to investigate deeply and start where you came up with your first knife model, I think the Odin.

So how did that landscape and that experience inspire the design and the way you built that knife?

Well, the Odin was actually a design that me and my brother made originally. I didn't know anything about knife design I didn't know anything about nice at first and we just knew kind of a simple concept that we wanted to go with and.

[8:10] He put some things on there I was working bail enforcement when we first started and I wanted a glass break on a knife and A couple other things and that really is what started that and at the time, you know being new into knives I wasn't even really a fan of the wharncliffe style at the time.

Now if you ask me, it's the only knife I'll carry. It's pretty much the only style I carry.

But yeah, having that Odin really, we shaped it a lot because I.

[8:41] Was wearing heavy clothes and I didn't really want to carry a heavy knife. And so I started, modeling my knives after what I was carrying on a daily basis considering carry. So I wanted them smaller, lighter.

And I wanted to take up less space on my waistband, especially because sometimes you can get hot up there and sweat and I didn't want to rust blades because I don't, you know, at the time I didn't know anything about stainless steels.

I was just, 1095 was all I was using at the time. And so that kind of structured the start of why we were making knives the way that we were making them. And the Odin has come a long way.

If you look at our logo, you actually see the Odin design is right beside the Viking head. It's crucial to the landscape of who we are as a company.

It was never our best-selling knife, but I just love it so much.

It'll always be in our lineup. Always your first love.

Why the Wharncliffe? I am a lover of the wharncliffe and the historic sacks and the Scrama sacks and all that. But I remember when in the knife world.

[9:51] Wharncliffe first started becoming very popular. And they made me I don't know, they made me uncomfortable. I was like, this looks like I don't know, I don't understand. So why? Why wharnies for you?

Oh, the main thing for me is I love control over the tip of a knife. And it's a lot easier for me to have that control with that style of blade. And even on some of my new ones like my Fenrir, you'll see that I profiled the knife down. It's more like a modified Birdbeak, but I just have felt like the straightedge gives you the best for slicing, cutting, and I've used it.

I used it at first because that's how we designed it. I was like, this will grow on me. And eventually it did.

I mean, if I make a knife that's a different profile, I sell it.

And where some of these new like wharncliffe styles or even sack styles, I'll keep the first model for myself.

[10:45] Because the blade's really grown on me. And for my uses as an everyday tool, I have felt like it accomplishes what I need more so than, you know, your curved edge blade that you're going to use for honing or things like that. So how did that benefit you? I'm really interested in this bail bonds or bond enforcement. On a lark many years ago at this point, 15 years ago or so, I got my, process server's license just because I was working with a dude in video who was a tough guy and he did that on the side and I was like, that's cool, I do martial arts, I could do that.

And I never ever once did it, but I had this sort of romantic notion of that sort of side of things.

And I would imagine bonds enforcement has a similar, similar but way more dangerous kind of feel to it.

How were knives incorporated in that line of work and how did the wharncliffe shape in particular benefit what you were doing?

So at first it didn't and that's kind of what You know, I didn't really have an attachment to the one cliff The one cliff was more like it was you know, When me and my brother were talking about starting northern breed knives It was we wanted to make Viking style knives And so he incorporated his style with mine and put the glass break on it and really the glass break was what I was going for.

[12:12] Because we were the reason I got into is I couldn't afford a good knife. It's still in this day I can't, so I made my own. So I wanted to have a good knife in my belt because they were cheap and they weren't accomplishing what I needed to accomplish.

So I wanted a glass break on one and I made one because of an experience that we came out of. I had a guy almost run me over in a car and my partner was trying to break into the window and he couldn't get in. So that was where it started.

And then it just grew into this thing where it's like I gave up bail bonds because I wanted to make knives after that. And so it started out of a need. In fact, our mission statement is made from necessity built for a purpose. Because when we made them, it was my dad was buying, Winkler's and Lion's heels and all these Medford knives. And eventually he was like, man, I'm tired of spending money on knives. So I'm just gonna buy some stuff and make it.

I was like, this is perfect time for me to get into it.

And so I started just getting out in the shop. And in fact, my first knife I modeled after a Winkler belt knife, and it was absolutely horrendous.

[13:25] But yeah, so me and my brother started talking. We went to the Wharncliffe Shave, and I've just never gone back.

I mean, I literally use that saw knife every single day.

Wow. Your dad sounds like a true knife junkie too, man. Going for all the big ticket items there.

Well, you know, we grew up not far from Boone and my brother actually worked in Winkler shop for a while, which is where he kind of found his love for it. And I just, you know, learned from him for a little bit and then just ran with it myself.

Man, it's a small world, especially the knife world.

So let's talk a little bit about how you make a knife and what your design process is.

I've noticed lately that your, as I mentioned up front, your design range has expanded.

Tell me about how you design a knife and then I'll ask you when you're done telling me that about how you actually go about making them.

So these new designs, what goes into that?

So it depends on what I'm trying to accomplish with a knife some of my golf or popularity like, The dynamics blades that are really popular. I wanted to make a double-x blade So I've kind of dabbled in that for a while and to make my own version, but most of what goes into it is what I'm trying to accomplish and.

[14:49] You know, that's one of the top right there was and I probably never take that down because that's the original Odin but.

[14:56] But a lot of what goes into my process is what I'm trying to accomplish.

This knife right here that you're going over right now is what I carry on an absolute daily basis. It gives me the option to pierce, stab if I need to, or straight edge to really cut.

And so I do try to design function for the most part. And then there's some styles like that Quaken that you just passed that I made because it's popular style and I wanted to make one of my own. And so when I'm designing a knife right now the biggest thing for me is handle and the way the handle is and how you carry it. So if you look through my design process through my knives they've, my handles have changed drastically because I've just been working as hard as I can to come up with a good functional way to carry a knife where it fits in your hand naturally and that's why the way that we sculpt our handles are the same on every single knife. We call that our custom copper head sculpting. I mean it's going to be the same every knife that you go to because when it goes in your hand I want it to fit like a glove and feel like it's made for your hand. And so the biggest design feature for us is the handle. The knife I always do just based off of you know what I'm trying to use a knife for. But the biggest part for us is having that good functional when you pull it out of your sheath, you know that it's going to fit in your hand and it's ready go.

[16:25] Handle, so I'm a daily fixed blade carrier myself, but I live in a very suburban lifestyle.

[16:33] And so I don't carry it on my belt.

I keep it tucked in my waistband, and to me, handle is huge.

[16:40] I have a large collection of fixed blade knives that are sized for daily carry, but I only find a fraction of them comfortable on a daily basis.

Part of that has to do with, like a huge part of that has to do with the handle. How you know how it how it carries next to my body because it's so close to my body. It's not offset by a by a belt or anything like that. It's it's right up next to my body. So for me, I like it a little bit shorter or you know, I have my own preferences for my style of carry. What is your style of carry? And and does does the handle design play into that?

Oh, absolutely. So I'm going to show you one of my nice guys sitting right here and this is actually one of my newer designs. So a lot of times like for instance the church we go to it's a big church it's really packed, and so you're in a tight compact spaces all the time. So this little knife right here is one of my newer designs it's the seer and I designed it if you follow, long enough I have a push dagger and this is kind of based off of the handle of that it's really made for your hand to fit and honestly I can get I don't I don't have huge hands, but I can get four fingers on there.

And the way that I do it is I literally made that to my hand and hopefully to the point where your hand, cause you can see, I can still get a little room on there.

[18:04] And the way that I carry is I love appendix style. So I carry a CIG P365XL appendix.

And I actually carry this little scalp most of the time on my appendix as well, scalp carry like this.

So that way I can reach and I'll actually pull it out of my sheath left-handed.

So that's one of the few.

You know, designs that I've made to really in tight, compact spots where you're talking about, like where you can't really afford to carry a big knife or sometimes even carrying a vertical knife inside your waistband, it's uncomfortable, it'll take takes up a lot of space. And so I made that to fit a need for me to carry in those tight spots where I could still have function to get to my blade if I can't get quite to my gun. I carry outside the waistband, but it's because of where where it's at, it's covered up. And I can still get to it easily and I'm not uncomfortable carrying it.

[19:05] The appendix style carry or so you carry it scout style. So that's horizontally on your front. This is an interesting thing because I've basically heard universally that's the best place to carry anything, any sort of, you know, weapon that you plan on using in a pinch because it's the most accessible.

I used to think scout carry on the back was really cool and I used to carry back there and then I fell on it once and I was like that's not cool at all.

So I moved it over to the side and the side feels good but you know and I'm right handed and it draws right handed just great but you know reaching around with the left hand, not so easy especially if you find yourself face down on the ground.

[19:52] Way, you held that up that knife too quickly if you could hold it up so we could check it out. That's beautiful, beautiful wharncliffe style blade with that, with the sort of instead of that curved tip, you've got, you've got that angled tip. It's, beautiful. What is that like a three and a half inch blade?

Yeah, so it's six and a half inches overall. And for like, kind of what you're talking about, I when I carried appendix style when I pull this knife out I'm pulling it out like this and it gives me this option to come from here out if I need to so I'm not having to reach across my body to carry it appendix style I just know what my hands are going to so my left hand is going to my knife and my right hand is going to my gun so you know it's it's definitely something I've messed around with this, I carry a lot and I hate being uncomfortable when I carry stuff, which is why.

[20:51] I've even changed my knife the way that I make them now. I mean See if I get one of these So this is one of my newer knives here, but I mean, it's just really super thin I use 3 16th inch g10 and 1 1 8th inch steel. This one's 3 16th inch steel But I want this knife to be super thin because it's my philosophy. So when I carry a gun, I'm carrying a gun that's super comfortable to carry but can still accomplish the goal. And so I want a knife that's super thin, functional, and just easy to carry and you don't even know it's there.

So that's the design part for me. I mean, it's got to be comfortable, it's got to be functional, and it's got to find its place in my belt where it goes to the side.

Okay, so that's a huge thing right there.

Because you're talking to a crowd who does carry a lot of stuff.

Knives, of course, it's usually more than one.

And then you got your flashlight, you got your keys, you got your phone.

Some of us carry pistols, you know, a lot of wallet.

There's a lot of stuff and then a lot of EDC fans, if you will, or, you know, that have a nice pen on them.

They also might have a fidget thing or a challenge coin, like all this stuff on them.

So how do you convince someone that a fixed blade knife is the way to go?

[22:11] Yeah, that's a task in and of itself. I've got a couple people that had followed my page, but they won't carry a fixed blade.

And I've learned in this community that people find what they like and whether it's the right way to go or not, they're gonna carry what they carry.

[22:30] I like a fixed blade because there's no moving parts. If I've got to get to a blade fast, I don't wanna have to worry about flipping it open.

Same reason you wanna have a round in your chamber if you're carrying a pistol.

I mean, any extra motions that cause for a failure It's not something I want to deal with and you can practice all you want to and and I'm sure there are guys out there that practice a ton with a you know, A folding knife and would tell you that's their great carry and and good for them if they can do it But I think when you're in if you've never been in a adrenaline driven situation and know what that pressure is like.

[23:10] You know There's a different story That's one of the reasons I like some of these the way some of these like gun companies are training now It's hands-on. It's putting you in the action. It's adrenaline based so you can feel that pressure, Because without that you really don't know how you're gonna function when you carry it So for me, I carry a fixed blade one because I can make them I'm working on folding blades right now for those that can't but I like a fixed blade because it's just simple, right?

I mean I can get to it. I've messed with my knives enough where I know where the edge is at I know what I'm doing with them and I don't have to worry about it folding down on my hand because I didn't lock it out Right or anything like that. So For me if you're carrying in an everyday carry, For self-defense the fixed blade makes the most sense find the style that fits your needs the best But stick with a fixed blade because it's simple. It's easy and You know, it's just a good tool man. I I, I can't say enough about them. I do like a good folder every now and then but.

[24:13] I just carry so much fixed blade now that I probably, you know, I'm not gonna spend my money on a folder anymore.

Yeah, yeah, I have a sprawling folder collection. I love folders. And some of them are, you know, made for easy deployment, you know, like Emersons and that kind of thing.

But since starting to carry fixed blades, you know, several years back, I always consider that first my self-defense option if I'm gonna use a knife for self-defense.

And I've done, you know, a bunch of training on that over the years.

And so I feel somewhat confident in my abilities, though pressure testing is the test.

And thank God I haven't been put to that test.

But I think I would try and pass it with a fixed blade and I'm always carrying several folders, but that's for a different reason.

That's for opening boxes and playing with. I mean, I hate to put it that way, but oftentimes people who collect knives, such as myself, are interested in the materials, the design, the feel, the action, different things than you might be interested in if you're in your fixed blade.

Oh, right.

[25:23] Yeah, so for me, fixed blade equals self-defense. Folders equal everything else.

Oftentimes it's not socially acceptable to just pull out a fixed blade and use it.

People are, you know, you get a bit of that.

At least where I live, you do. But I've been working on normalizing it.

So we'll see how that works out for me.

But okay, so let's talk about how you make these things now.

Because, you know, knife making, it's something that you came into not out of a great love of knives, but out of a real need.

So just tell me about your approach. Well, it changes drastically. I mean, if you look at how I was making knives when I first started versus how I make them now, I mean, it's a completely different ballgame for sure.

[26:11] Really, the thought process for me is steel. And when I started, I was making with 1095.

You know, ESEE made a lot of their bushcraft knives with 1095. It's a good steel, probably not the best deal to start with if you're starting into the knife making world.

But I liked it. It was a good durable steel. So I started with it. And then as we started kind of shifting our mindset towards the, I guess you'd call it tactical world, or we, switched to ADCR-V2 for the edge retention on them. And it's just a good solid steel.

So the way we do it is we get stock steel in and we get it in bars. And I basically just draw my designs on them and use a bandsaw to cut them out. And then we go through several different layers. I've seen people do it several different ways. I bevel my blades before I I do the heat treat process I get like a 85% bevel on them. I take a 36 grit belt and I put the initial bevel on them.

And then it will go through the heat treat process, the normalizing process, the temper process.

And then when I'm done with all of that, I come back and I'll put the final bevel onto it with a higher grit. Usually I go up to about 400 grit.

I'm not trying to get a super polished finish on these. These things are made for self-defense.

I don't need you to see your image in them.

And there are some knives that I will go a little higher on depending on what I'm doing.

[27:41] And then sometimes knife making is just messing around. Like that sear that I showed you a little bit ago, that's like a nail polish finish trick that I learned from somebody and I just wanted to try it.

So we went through that.

But I acid etch all my blades after we go through the temper.

And after I acid etch them I go to a black oxide and depending how I'm going to finish the blade whether it's gonna be like a stone wash finish or just a black oxide I will either seal them.

If you get cast, well it comes with a sealer that comes on to protect the blade at the end, and I'll either stone wash it before or after I go through that process.

And then you just go into handle making which is just for the most part, Most of my self-defense I use G10. I have gotten into making work some custom knives where you know, If you're just carrying a knife that you want to love i'll actually make the handles myself and you'll see some of the kind of designs that i'm Um, depending on what colors you pick that you want in them things like that, but for the most part you're getting this, you know, just.

[28:52] G10 um I think g10s for me. I stuck with it because my carda holds in alaska, you know if it gets wet, you're holding moisture. And so I wanted something that didn't really hold a lot of moisture, but was pretty good about durability. And I mean, G10, you can just beat death and it's gonna, it's gonna work, right? So it fits into that whole mold of, you know, built for a purpose, right? Yeah, oftentimes, in testing, this is not my own testing, but oftentimes in testing, it's the steel that will fail before the g 10 fails. Yeah, I've heard that a lot with folder testing, especially like cold steel and companies like that that do abusive testing. It turns out oftentimes it's the blade right near the ricasso, you know, that breaks. I want to go back as a second to the beveling part. Oftentimes people I'll hear people say that they, do all of the beveling after heat treat and and I always wonder about that as a non-knife maker because I do know that the steel is...

[30:01] Is much harder after the heat treat. So you're going to go through more belts, but also you stand the risk of, you got a lot of metal to hog off, if you're going for the bevel after the heat treat.

So there's a lot that you can go through a lot of belts.

But also you run the risk of ruining the heat treat by overheating the steel.

I mean, I know people know what they're doing and they cool it as they go.

But it just seems like a shorter process to do it the way you're doing it.

How did you, why did you start doing it that way?

[30:36] Luck of the draw. I mean, you know, I, I, I, when I started, I watched somebody on YouTube and I just kind of, you know, took my own process from it. But, um, the, the part that I'm really picky about, and if you ever came to my shop and worked with me, um, I'm very picky about how I do my heat treat and normalize part.

So because really where you mess up and where you're getting a lot of, you get warps, which is what a lot of people worry about when you pre-bevel your blade, right?

And so a lot of times people won't do that bevel beforehand because it makes the steel thinner, which gives you more of a chance for it to warp.

[31:19] And that's generally caused by you overheating the blade as you're heat treating it.

Now sometimes it could just be that you've got bad steel or whatever it is that's causing it to warp.

But I have a couple processes that I have set up to ensure that.

One I heat treat with the light off.

So I'm checking that temperature based off, I want it to be almost a salmon color, right above non-magnetic. So I've got a magnet that I'm checking it with.

And then, because I don't want a flame coming out as soon as I hit the oil, because if I do, it generally means I got it a little too hot.

But for cases like that, I have a vise set up behind it with some angle iron that I'll throw it into, kind of help it cool back down into the straight blades.

That way you're not messing it up and the temper will a lot of times take out that little bit that's left if it is.

If you overheat those blades, that's where people are worried about. It's less.

[32:17] Work, I guess. In the long run, you're taking belts and stuff, but you're not having to worry about warps or things like that. And so it's just one of those things where I did it that way and I got so picky about how I do my heat treats that it's easier for me to do it and have it mostly done because when I come back and I bevel it afterwards I'm running my grinder on about 50%.

I'm not even running it at 100 because I don't want too much heat on that blade because your.

[32:48] Blade is important and you don't know it but you could accidentally get it way too hot without knowing it and take a lot of that stress, add more stress into the blade and it's not going to be as durable.

And I'm not, you know, the world's expert. I'm just going by my experience of what I've learned from doing this for a while is that, you know, I just don't want a lot of heat on the blade after that temper process, right?

The way you describe having the lights off when you're heat treating, you know, it sounds very much like someone who forges knives. And that's, you know, how they check, you know, and it's, it seems like a lot more old school, like the way it's been done for most of history.

You know, you're doing it kind of by feel.

And so how much of the, but you're also doing stock removal knife making.

It's kind of an interesting blend. What are you heat treating in?

Is it in a forge or is it like an even heat?

No, I use a forge. If I had an even heat, I'd probably put in some S35E or something like that. But I'm old school.

And so I started in a forge and I just do everything in a forge.

Forge. That's just the process that I started and I've stuck to it.

[34:04] It's hard because you want to change, you want to evolve, but you also know things that work and you want to stick with those things too. So you kind of got this always balance of grow and change, but don't lose the heart of what you do at your company. And it's a balance for sure.

I mean, that's a really cool blend.

Well, cool is, it's a very unique blend of those two processes.

I don't think I've heard that before.

Maybe I have, but I like it because, you know, I've been in shops where people are forging knives, and that's the part to me, when I first saw it, that was the part to me that seemed like the mystery of steel, you know, like at the beginning of Conan the Barbarian.

It's like, you don't have a machine beeping I've been telling you when it's ready, it's you gotta have good eyes.

What's the color? And not everyone, it just doesn't seem like something that everyone would be maybe comfortable doing or familiar with or capable of.

[35:04] I like that, I like that blend. And then you talk about, well, how do you grow with something that specific?

You know, that there are different ways to automate certain parts of the process, But that, the sole of the blade, the heat treat part, that could be the most difficult place to automate or turn into a more, what am I trying to say, a more prolific process. Like if you're trying to make more and more and more knives faster, faster, faster, that's the part where it would slow down.

Where are there places to automate in your process in your process still maintaining that part of it?

The hatred is really the only thing I'm super picky about. about. I mean, I do whatever I can to speed up the process anywhere else.

But I have this philosophy and I've talked to several knife makers who do not share this.

This is just me, but I think the heat treat is the heart and soul of the blade.

And your knife is only as good as the heat treat. So that's the part that I'm going to do the same pretty much all the time.

Because I've had guys suggest sending them off to other companies and having them do it.

And there's something about that for me. It doesn't feel like my knife at that point.

[36:21] But I spent money on getting a good bandsaw so I can cut everything out of metal where I was taking an angle grinder or a grinder and cutting it to shape.

Time is money and I'll do anything I can at the same time.

But there are aspects where I try to keep it traditional for myself as well.

It's this weird balance that you find yourself in where it's like, how do I stay true to who I am and still adapt enough to really move forward.

Because the biggest struggle for me is knife styles. I mean, the style of knife I make is not the most popular knife style out there.

And there's been plenty of times where I'm like, I just should go with what's popular and make that and sell that. And I've had to say, no, you know, this is how we started, this is how we're going to, stay.

[37:11] Because like, I've got all these cool knives over here that I don't carry because they don't fit my blade style. And I'll make them.

Like I showed you this Vengeance, this is the newer model, but this used to be one of my most popular blades that sold. And I just love the blade.

It's a great blade. It feels good in my hand.

I just don't carry it because it doesn't fit for me. And so I've tried to keep true to how I started, where I want to be, and maintain sight of that.

Hopefully people along that time, as long as I'm making knives, will eventually say, hey, there's a reason they're doing things this way.

And it is hard because you see all the, a lot of times you see one style of knife come out and everybody starts making that style of knife.

And I've tried to avoid doing that, but it is hard sometimes not to jump on that train as well.

So what do you think those popular styles are? I don't necessarily know that I go by styles.

I think sometimes it's more companies.

People are going to do whatever certain companies are doing and they're going to try to make that style knife. I mean, I think one of them you can definitely say for sure is Winkler.

People just, you know, he's so successful. Why not try to copy his style?

And you'll never copy him. I mean, no offense. Nobody's Daniel Winkler, right? and, But I see it a lot with dynamics people have tried to copy that razor back. I mean everywhere it's.

[38:40] And I think the knife style is good. I'm not nothing against that I just you know, somebody innovates some sort of style and everybody else wants to do it.

[38:51] And I think that's where I struggle with the knife community a little bit but I've seen other fixed blade makers struggle with the with the Pekal style of knife you know the tip down edge in style yeah I'm personal adopter of that I love the call it's I love I love all knives you know almost equally but you know past couple of years the Pekal style knife because of Libre fighting and and Ed Calderon and and also this idea that you can use it without you know when you're in caveman mode when you have the adrenaline dump kind of thing, has made them very popular, but I know some people just really dislike the concept and the design, and I totally understand that.

Is that the kind of thing you're talking about, like something that has a flashpoint of popularity that you're like, eh, maybe I could make a couple of shekels?

[39:42] Yeah, yeah, well, I mean, the Pacal style, I tried to do it myself.

Honestly, because of the way that I carry a knife, I mean, my first grab is here, so that knife made sense to me.

I just could never make one that works the way I wanted it to.

So I left that one behind.

But yeah, it's that kind of thing. Like, you know, ShivWorks kind of came out with that clinch pick and that thing took off and then everybody's making those Pucallis-style knives, right?

And I think they're great. So I wish I could figure out how to make one that I felt worked the way that I needed it to, but every one I've done so far has just been a flop. So.

[40:22] Well, the bandwagon thing is kind of interesting and also I feel like sometimes knife makers.

[40:31] Start off with a fixed blade because in terms of process, there's less engineering.

But there's always this pressure, like oh I gotta make a folder.

And what I can't figure out is if that pressure is something that you feel due to market forces Or is it something that a knife maker feels because they're a knife maker and they love knives and that's just another knife they could do?

Well, I can tell you for me, so me and my brother, Polite but Dangerous Tools, we're actually doing this thing right now called our Brother vs. Brother Challenge.

And what we're doing is we're coming up with this crazy, you know, challenge that we're both going to try to compete, complete and then just put them out and let the world see.

So in our first challenge, we're actually doing a folder. And for me, it's more of expanding my skill set because, I've always struggled with monotony in jobs, which is one of the reasons I love knife making.

If I get tired of a design, I just make a new one. I just go back to the drawing board and figure it out. And so I want to make a folder for me because I want to be better. I want to learn more stuff.

And if you've seen any of my blades from the time I started to where I'm at now.

[41:47] I'm consistently changing things to make them better. One, it helps me stay motivated, and just in this business because I want to make my stuff better for you, for me, for anybody that's carrying it.

And so the folder thing, yeah, there's some of that. Like everybody tells me down here, because I live in Georgia right now, and nobody carries a fixed blade here.

It's like, you got a pocket knife.

And so I do feel that at a point, but there's also a point where it's like, I want to see if I can do it.

I want to see if I've got what it's made of.

I don't have a mill. I wanna see if I can do this without all the fancy tools and equipment and just see what I'm made of.

And so I think there's a, it depends on the person, there might be some of that pressure, but some of it is just like, I wanna expand my skillset, right?

Yeah, yeah, yeah, absolutely. And well, what you were saying about monotony in a job and how you just kind of design something new, make something new when it's feeling monotonous is interesting to me because that brings you to a certain kind of business model because there are knife companies out there like Chris Reeve Knives who has several models, and they have perfected them and they update them every 20 years or so and they're just, man, they're the best folders out there, one might argue.

[43:12] And then there are companies like Topps Knives who, And I love both of these companies, like to the core of my being, but they're both very, very different.

Topps Knives has 8 million, billion designs, and most of them are available all the time.

And there's, you know, a relatively small shop in the United States.

So you have this huge body of designs and a small body of designs, two different companies.

And what you're, the way you're describing kind of seems more like in that tops vein where you're excited to try new designs.

And so how do you see that sort of instinct shaping your company as it grows, you know, across time?

So I've got a couple of knives that I'm not getting rid of that'll be always a staple in my, now I may change things like a little bit of the handle or whatever to make it a little bit more functional or whatever.

I got to make a buck too, right? And so every now and then when I just want to do something different and see how it works, I'll make something new. But like my thin rear, I'm always going to make that knife to me out of all the knives I've ever made. It's my absolute favorite.

[44:29] Do you have one right there with you? So years ago, when I was trying to get into the knife for all, I thought I was, like I said, I was doing bell recovery at the time. And there's a guy named John, his Instagram handle is UniqueSkillset. He's on a TV show now. They live down here in Atlanta, or Gainesville.

[44:54] And he got me into bell bonds. And so I wanted to make him a knife. And I made this knife called the Fenrir because that's the name of their company. And it was terrible. But at the time, I thought was the greatest knife I'd ever made. And so I sat on that design for I guess two and a half years now and just have looked over and looked over it and it's the only model of knife that I haven't revamped two or three times. I have literally made that first one and it was a botch and now I went back to the draw board for two years and put this one out and when I say I I carry it every day, unless I'm in a super tight, compact place where I carry that little sear.

The thinner is what I carry hiking, it's what I carry to the store.

And I carry the same way, appendix, scout carry.

And it's just, to me, it's got both utility and tactical in it.

And it's, it's so that that knife will be a staple in my line as long as I can do it.

It's not very popular. I hate that because I feel like people are missing out on it, you know, a good style blade, but that's the one that I probably will never change.

But that one and then I, you know, this vengeance I've made a couple of times, which is this.

[46:17] You know, my version of a Persian can jar.

And so I've got that one that'll stay in my lineup for a while and my Odin will be there forever.

But you know, when I get tired, I make little things like this knife right here.

This is a double edge, called a Ravager. I've actually started.

[46:39] Several years ago, I designed a knife for Raul Martinez, and this is a couple years down the road version of it.

So, every now and then I just bring back old models too and remodel them, you know, put new paint on an old car and see how it does.

That Fenrir, I have a feeling that Fenrir is going to take off. You've been posting a lot of pictures of that, and that Damascus version that you just held up.

And it is beautiful and to me it seems like, when I was talking in your intro about how I've seen, your designs and your knives become more refined, that's the one I was thinking of in particular, because it just seems that way.

It seems more, it seems like it took more work to perfect on the grinder.

[47:27] And that's just me spitballing, but I think that knife will take off.

I'm glad you're not gonna get rid of that or phase that out.

That one deserves the full play. In terms of going from bonds, bonds enforcement to full-time knife making, what was that choice like?

Well, we moved to Alaska, I stopped bail bonds anyways, and I was just doing security at probably the coolest store.

I mean, down here in the South, would be the best store ever. It was a grocery store, liquor store, and a gun store all in one.

[48:11] And so when I was there, you're just fighting people over, I mean, knocking down shelves in the gun section, trying to fight people who were stealing. And I was doing that in Alaska.

[48:24] I don't know, my wife just was finally like, I was coming home from work from there.

And then I was spending hours in the shop. And so I was gone, sometimes like 18 hours a day.

And she was like, I think it's time we take this full time. We stop doing it.

And I was like, I'm not gonna stop doing it. So might as well take it full time.

And one of the biggest things that pushed us, or a big reason that pushed us back down to the South is that getting materials that you need in Alaska. There's some companies that do it, Simper Sharp, they seem to know how to get all this stuff.

[49:00] And he's a super nice dude, lived right there in Wasilla too.

But one of the biggest things for us was we couldn't get some of the stuff that we needed to make better knives.

And so we just decided, you know, my wife's family lives down here and we moved back.

But it was it was it was either security or nice and i like nice to stop so.

Yeah and and that a point you know you also if you have children or you know as you get older it's like i want to make sure that i come home every day and you can never make sure but you can head your bets by not working security and a liquor gun store.

Well, and you know, I'm getting too old to be fighting people.

You know, when I was younger, sure, that would have been my jam.

But you know, we got I got into some knockdowns where it was like the next day it was hard for me to get out of bed.

And I just, it was one of those things I can make tools for people that want to do this.

But I messed up my knees so bad wrestling that it hurts me to fight people.

But I just would rather do something that I can work with my hands and pick them all in hours, and still go to my kids' ball games and stuff. So.

Amen. So how does your wife fit into the business?

[50:22] She tells me if my stuff sucks or not. So I generally I'll show her a knife when it's done and she will give me an honest answer. Now she doesn't know a lot about knives, but I get, I hate this knife quite a bit.

But she doesn't like straight edge knives either. And so because to her, she's grown up around curved knives, hunting knives.

And so she is not a fan of the straight edge, you know, wharncliffs, bird beaks and stuff like that.

And so she hates a lot of my stuff. But she's very supportive.

And I mean, honestly, if it wasn't for her, I wouldn't be making knives.

So, she's a big part, more of a support part than...

She doesn't help me with anything.

[51:10] It's my business, she's gonna let me run it. Cause I wish she would help me pack stuff up because I hate shipping stuff.

But yeah, she's a big part in not a big part of the same time.

Oh, that's kind of the best of both worlds in some ways. You get the inspiration you need, but you're also left to your knife instincts.

Because if you were part of the company in a more design way, you might be making bowies right now or something like that.

My dad's wanting a bowie, so I might have to make one here soon for him.

Hey, you meant I saw you made a tracker. So if you make a tracker, you gotta make a Bowie. I mean, classic American knife.

Listen, I'm a big I'm a big fan of the movie hunted. And, you know, that kind of, I've never made a tracker. And I just made this one off for somebody who, you know, they came on hard times like a lot of people and couldn't get it.

And so it's actually still sitting downstairs, but I do.

I love a good tracker, but just because I like Benicio del Toro throwing one into the tree, right? Yeah.

[52:20] The hole he made in that tree throwing that knife was always impressive to me.

Oh yeah. That made me think I never needed a gun. Just a knife, right?

Yeah, right. Exactly.

So as Vandre Knives grows into the future, this is, you know, this is your, your company, how do you want to see it grow?

What do you want to see it turn into? That's a good question.

Honestly, my goal has just been to help people that need it.

And so, I've always, I try to help a few local law enforcement around here if you need one.

I try to help as reasonably as I can to get them into people's hands because I don't make a ton of money and so I've got to make a little something off of them.

But my goal has really just been.

[53:05] Give tools to people that are in those spots that really need them.

And so I'd like to be more involved down the road with law enforcement and military guys and just really helping there.

That's kind of my heart. I started my career as a detention officer for South County Sheriff's Office in North Carolina and didn't last long before my wife wanted to move from North Carolina to Georgia.

So I've always kind of had a heart for those guys. My brother was in the military for a long time.

And so really, that's why we shaped and designed this stuff.

I mean, I'd love for regular people to buy them too, because I think that they're worth it and they'll help you in a pinch.

But really want to just see guys that need good tools on their belts, pick some up.

But I think that's hard now, because there's a knife company on every corner.

It's almost like churches in the South, right?

Would you, what would it take for you to give over some control over your product if you needed to.

[54:11] Or when you need to, to hire employees and have someone else working on your knives?

Would that be a difficult step for you to take in terms of the knife making part?

Oh no, I don't think so. I think as long as, so, I think just setting up policy and procedure to make sure that the stuff's being handled the way that I want it to.

[54:35] I can't insure you every time that something didn't happen in a blade. I can't see everything.

I'd love to have eventually to the point where I needed other people to help me do it, but I'm not at that point right now. If I got there, I'm sure I could trust people to do it.

I think that's what makes good leadership is just being able to trust other people to do, what you need done yourself. If you train people the right way, it'll be done the way that you want it done, right? And if you get the right people in place.

I would love to get to that point. If I could stop getting banned on Instagram, I may get there.

[55:13] Yeah. Yeah. I mean, I have no doubt you'll get there. And especially with what you just said about leadership, and being able to trust other people and delegate to other people. I think that the difficulty sometimes knife makers run into is, their attachment to their work can be more like an artist's attachment to say a painting or a sculpture, where it has a certain preciousness where you're like this is my painting, no one else can do my painting.

[55:46] And I totally, I can understand that having been a painter myself, I understand that instinct.

But at the same time, well, like all the big time painters of the past, they had big shops full of painters who did all the stuff and they just did the hands and the faces and the hard stuff, you know, the horses and stuff like that.

But yeah, the ability to understand that you are making tools, I mean, your goal is to get these tools in the hands of people who need them, that you're making tools and that you can trust someone to the process and trust in yourself that you've kind of passed it along properly.

Right. Yeah, and I think it's one of those things too is that it's not hard to make a I mean, it's hard to develop the skill and bring people into that, but...

[56:44] I've always wanted to, in fact, most of our stuff that we do outside of the knife world is trying to develop people.

And so that would be a big part for me. I always make the designs, right?

Because Van Rare is my heart.

But I would love to be able to help guys that have never made a knife before come in and off the street and just be able to make one.

So I'd love to get to that point and just develop people. The knife world needs more knife makers.

We need more people style.

We need to develop this community. So I'd love to be a part of helping it make bigger and stuff like that.

That's awesome. I should have done this way earlier, but let me see every knife you have before you.

[57:30] Just so that people know what we're talking about.

All right, so I've got my quick pick right here. I'm actually hoping that this knife have a collaboration with somebody later on down maybe in the next couple months that's my one of my newer style knives I've got the seer that I showed you guys my fin rear this knife is actually one of my favorites too this is the tear I developed it so you could have a good this was before I finished the fin rear but so you have a good stabbing point but also a good straight edge with a slight curve to it. So, you know, you've got good movement on it. I carry this one quite a bit too. And then I showed you my Fenrir.

Show it again.

Yeah. This is my absolute favorite blade. I carry it with, you know, the outstrap on there. And then I've got, I brought this big beauty. I don't sell a lot of these anymore.

[58:33] Yeah, this is one of my tomahawks that I made, the iron side.

I've got a couple new axe designs coming out here pretty soon.

So I'm pretty excited about that because I love axes.

And then this is my Vengeance. This was one of my more popular knives, but this is the newer model of this knife.

So that's it.

[58:56] That's all I got with me right now. Well, yeah, people can check out your website and your Instagram feed.

And it doesn't surprise me that Ethan Curtis of Vandrer Knives likes axes.

It kind of makes sense, right?

Yeah. Well, Ethan, thank you so much for coming on the Knife Junkie podcast and sharing this stuff and your experience coming up in your knife career.

It's been a great joy and greatly appreciated, sir.

Hey, well, thanks for having me on. I really appreciate it. It's been a good time.

My pleasure. Don't take dull for an answer.

It's the Knife Junkies favorite sign-off phrase and now you can get that tagline on a variety of merchandise like a t-shirt, sweatshirt, hoodie, long sleeve tee and more.

Even on coasters, tote bags, a coffee mug, water bottle and stickers.

Let everyone know that you're a Knife Junkie and that you don't take dull for an answer.

Get yours at theknifejunkie.com slash dull and shop for all of your Knife Junkies merchandise at theknifejunkie.com slash shop.

To the Knife Junkies YouTube channel at theknifejunkie.com slash YouTube.

There he goes ladies and gentlemen, Ethan Curtis of Vandrer Knives. I love that Viking style of knife, you know I talk about it probably all the time. But don't Don't get sick of it, there's a lot of great stuff out there.

And Ethan's Fenrir.

[1:00:23] Who is, Fenrir was a wolf, right? Fenrir is a wolf from Nordic myth.

I'll ask him in the extra, the interview extra that you can get on Patreon.

Just go to theknifejunkie.com slash Patreon and you can hear interview extras from every guest we have on the show.

And I have a couple of other questions to ask him and we'll get to that shortly.

Thanks for joining us here on the Knife Junkie podcast. Be sure to join us on Wednesday for the midweek supplemental and Thursday for Thursday Night Knives 10pm Eastern Standard Time right here on YouTube, also on Facebook and Twitch. Whatever, that is. For Jim working his magic behind the switcher. I'm Bob DeMarco saying don't take dull for an answer.

Thanks for listening to the Knife Junkie podcast. If you enjoyed the show, please rate and review at reviewthepodcast.com for show notes for today's episode, additional resources And to listen to past episodes, visit our website, theknifejunkie.com.

You can also watch our latest videos on YouTube at theknifejunkie.com slash YouTube.

Check out some great knife photos on theknifejunkie.com slash Instagram, and join our Facebook group at theknifejunkie.com slash Facebook.

And if you have a question or comment, email them to Bob at theknifejunkie.com or call our 24-7 listener line at 724-466-4487 and you may hear your comment or question answered on an upcoming episode of the Knife Junkie Podcast.

[1:01:50] Music.

Share This With a Friend >>>

For early access to The Knife Junkie podcasts and YouTube videos, receive Knife Junkie stickers and be entered into the monthly knife drawing giveaway, join The Knife Junkie’s Patreon group of awesome supporters.

Let us know what you thought about this episode. Please leave a rating and/or a review in whatever podcast player app you’re listening on. Your feedback is much appreciated.

Please call the listener line at 724-466-4487 or email bob@theknifejunkie.com with any comments, feedback or suggestions on the show, and let us know who you’d like to hear interviewed on an upcoming edition of The Knife Junkie Podcast.

To listen to past episodes of the podcast, visit theknifejunkie.com/listen.

StreamYard simplifies the process of live streaming and recording videos. It allows you to create content seamlessly from your browser. With its versatile features, you can multistream to various social media platforms, host regular shows with guests, conduct webinars, record podcasts using local recordings, and create videos with ease. StreamYard has become a popular tool among live streamers, video creators, YouTubers, and podcasters. Its impressive array of features includes live streaming, webinars, local recordings, screen sharing, and more, ensuring that you can produce professional and polished content every time. Get $10 in credit on StreamYard with this link! (new customers only)

Shopping for a Knife?

Support The Knife Junkie Podcast and YouTube Channel by Buying Through My Affiliate Links

eBay

Field Supply

James Brand

Knives Ship Free

Off-Grid Knives

Vosteed Knives

WE (Civivi) Knives

Other Products and Services

Podcast Hosting

Website Hosting

Groove (Free Account) – Replace 17 Apps/Services in Your Business

Knife Books

Rakuten (Cash Back for Shopping Purchases)

Upside App (Cash Back for Gas Purchases)

TubeBuddy (Free Browser Extension and Mobile App for YouTube Creators)

Follow The Knife Junkie

Visit The Knife Junkie website

The Knife Junkie Listener Line — 724-466-4467

Email The Knife Junkie

Follow The Knife Junkie on YouTube

Follow The Knife Junkie on Instagram

Follow The Knife Junkie on Twitter

Join The Knife Junkie Facebook Group

Affiliate Disclosure

In the name of full transparency, please be aware that this website contains affiliate links and any purchases made through such links will result in a small commission for me (at no extra cost for you). If you use these links, I might be rewarded credit or a small commission of the sale. If you don’t want to use these links, no problem. But know that I truly do appreciate your support.