Calvin Richardson, Custom Knife Maker and Designer: The Knife Junkie Podcast (Episode 647)

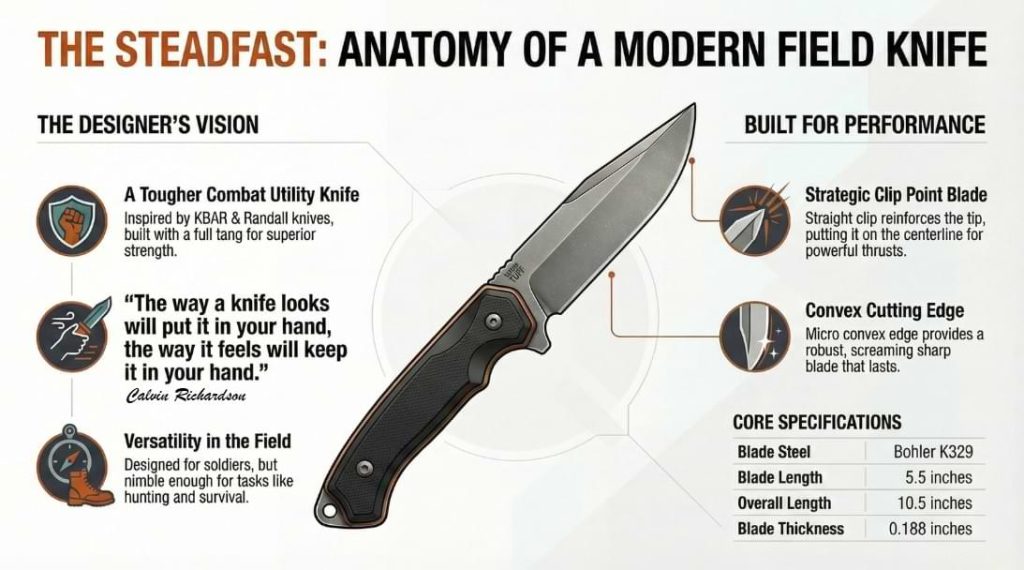

The Knife Junkie Podcast Episode 647 features Calvin Richardson, a custom knife maker and designer. Host Bob DeMarco explores Richardson’s transition from metal fabrication to blade making and the techniques that define his work. He also recently designed two blockbuster knives for Work Tuff Gear: the Steadfast and the Steadfast Large.

Richardson brings years of metalworking experience to his craft. His background in fabrication gave him the skills to work with different metals and understand how they respond to cutting, grinding, and heat. When he discovered knife-making videos online, he realized he already had the tools and knowledge to start creating blades.

“I was sitting there watching videos one day, and I was like, ‘I can do that,'” Richardson remembers. “I have all the tools. I have all the equipment. I know how to work metal.”

That realization sparked what would become a custom knife business.

The knife-making community has played a significant role in Richardson’s development as a craftsman. Fellow makers offered advice when he was starting, and they continue to share techniques and encouragement.

“When I first started, I had so many questions,” Richardson says. “And people just helped me out. They did not hold anything back.”

Richardson shares his work primarily through social media, posting regularly on Facebook and Instagram. These platforms allow him to show works in progress, connect with collectors, and build relationships within the knife community.

He also discusses the business realities of professional knife making, including the importance of proper pricing and managing customer expectations. Richardson learned that charging fair prices for his time and skill was necessary for long-term success.

Looking forward, Richardson wants to develop his own signature style that collectors will recognize immediately. He continues to experiment with different blade shapes, handle materials, and finishing techniques while building his reputation in the custom knife world.

Follow Calvin Richardson and see his latest work at Making Steel Dust on Facebook or connect with him on Instagram @calvin.richardson1981 to watch his journey from making steel dust to making custom knives that collectors are proud to own.

Be sure to support The Knife Junkie and get in on the perks of being a Patron, including early access to the podcast and exclusive bonus content. You also can support the Knife Junkie channel with your next knife purchase. Find our affiliate links at theknifejunkie.com/knives.

From fabrication shop to forge: Calvin Richardson of Making Steel Dust talks custom knife making, community support, and why collaboration beats competition on episode 647 of The Knife Junkie Podcast. Share on XThe Knife Junkie Podcast is the place for knife newbies and knife junkies to learn about knives and knife collecting. Twice per week Bob DeMarco talks knives. Email Bob at theknifejunkie@gmail.com; visit https://theknifejunkie.com.

©2025, Bob DeMarco

The Knife Junkie Podcast

https://theknifejunkie.com

Transcribe Your Podcasts and Videos: https://theknifejunkie.com/magic (affiliate link)

The Knife Junkie Podcast is the place for knife newbies and knife junkies to learn about knives and knife collecting. Twice per week Bob DeMarco talks knives. Email Bob at theknifejunkie@gmail.com; visit https://theknifejunkie.com.

©2025, Bob DeMarco

The Knife Junkie Podcast

https://theknifejunkie.com

Transcribe Your Podcasts and Videos: https://theknifejunkie.com/magic (affiliate link)

The Knife Junkie Podcast: Episode 647 - Calvin Richardson

[00:00] Announcer: Welcome to The Knife Junkie Podcast, your weekly dose of knife news and information about knives and knife collecting. Here's your host, Bob "The Knife Junkie" DeMarco.

[00:10] Bob DeMarco: Welcome to The Knife Junkie Podcast, I'm Bob DeMarco, coming to you remote. On this edition of the show, I'm speaking with custom knife maker and designer Calvin Richardson. I heard of Calvin first through his super successful design for Work Tuff Gear called the Steadfast. His take on the ultimate field knife. I was drawn to the knife for its elegant and aggressive lines and found it scratched my combat knife itch. Now, there is a large version of the Steadfast that's out, and it's on my short list, though it has sold fast. I think I have a bead on one, though, you'll all be relieved to find out. We'll talk with Calvin about the Steadfast and his handmade custom knives, which look beautiful too. But first, be sure to like, comment, subscribe, hit the notification bell, and download the show to your favorite podcast app. That way, you can listen on the go. Also, if you'd like to help support the show, you can do so on Patreon or on joining right here in the YouTube app. But go to theknifejunkie.com/patreon. You can sign up for a full year there at once and save 10%. That's theknifejunkie.com/patreon.

[01:14] Ad: Adventure delivered. Your monthly subscription for hand-picked outdoor, survival, EDC, and other cool gear from our expert team of outdoor professionals. Theknifejunkie.com/battlebox.

[01:27] Bob DeMarco: Calvin, welcome to The Knife Junkie Podcast, sir.

[01:30] Calvin Richardson: Thank you for having me.

[01:31] Bob DeMarco: Ah, it's my pleasure. And as we open, I just want to congratulate you on the success of the Steadfast. It seemed to just take to the skies.

[01:39] Calvin Richardson: You know, it kind of filled a niche in the market that really kind of needed to be filled, in my opinion. The Ka-Bar has kind of owned the combat utility market for decades. So this just kind of gave people, you know, a little bit different look in the same market, in the same style of knife.

[02:00] Bob DeMarco: So before I ask you more questions about this design, let me show mine off here. I love this thing. And then you came out with the large Work Tuff Gear and you came out with the large version, which now I have to get because that's just the kind of person I am.

[02:15] Calvin Richardson: And it's just a little bit more knife. It's just a little bit more blade. It's only an inch and a half longer because we go from a five and a half to about a seven inch. But it really does change the dynamic of the knife immensely. Changes the look and the flow and the way it feels.

[02:30] Bob DeMarco: Well, tell me about your goals in designing this and kind of specifically how you went about designing it and what you were going for.

[02:38] Calvin Richardson: I have a friend who has some connections to the Special Forces organizations and soldiers. And I was talking with him. I wanted to design something specifically for soldiers in combat. Something that would fill that role of a Ka-Bar, but be a little bit tougher. And he told me that a lot of soldiers really like that five and a half to seven inch length because it's long enough to do what they need to do if they need to use it in a self-defense situation. But it's also short enough that it doesn't get in the way of their other kit, which can really become problematic if they go much larger than that. He said a lot of folks really like in that five and a half inch range. So that's kind of what I started designing around.

[03:25] Calvin Richardson: Now, all my designs are always... I focus on the ergonomics almost as much as I do the blade shape or the usage of the blade because I've had a saying for years that: "The way a knife looks will put it in your hand. The way it feels will keep it in your hand. And the way it performs will keep you going back to it." And obviously, as a knife maker and a designer, I want you to go back to that knife as much as possible. I want you to hold it. I want you to use it as much as I possibly can. Because then that, you know, that's my goal. That's what I want to have happen.

So I really wanted to design something aggressive, something that had a lot of self-defense capabilities, but also something that you could use in the field like dressing a deer or something like that, which my son just did a couple of weeks ago with his large model. He got himself a nice buck, nice eight-point. And so even with a seven inch blade, it's nimble enough and light enough, you know. You would think that this would be a little bulky to dress a deer with, but he did everything with it and said that it worked perfectly. It just got in there and did what it needed to do. So I just wanted to design something that was kind of an all-around knife.

Just—and one of the things you will always find in my designs... I'm not a fan of straight lines very much except for like the clip. So you'll see a radius from the point of the spine to the butt of the handle. And that's always in every design that I do, you will find that. And I just feel that it causes it to flow better in the hand and it keeps that edge out away from your hand so you can do a little bit more powerful cutting. Those were the principles behind the knife design and kind of where I was going with it.

[05:05] Bob DeMarco: Uh, that overall radius that you talk about, that curve... I really like that. I see that—I mean, on a lot of knives I appreciate that. Even on folding knives, you'll see that sometimes. And what I really like about it is that it pushes that edge in a downward relation to the handle so that it's already doing some of the cutting for you.

[05:25] Calvin Richardson: Yes.

[05:26] Bob DeMarco: I really like that.

[05:28] Calvin Richardson: And also we'll take and move the tip more to the midline of the handle in relation to your hand so that on a thrust, you've got the bones and muscles of the arm backing up the thrust. So it makes for a more powerful thrust. And then in a snap cut, it keeps that the belly of the blade out away from your hand in front of it so that a snap cut, it's really fast and really powerful.

[05:55] Bob DeMarco: You said that you were interested in making a more tough or robust version of the Ka-Bar. Not version, but reimagining of the combat knife, looking at the Ka-Bar. How did you accomplish that with this design?

[06:10] Calvin Richardson: Well, it's kind of... So, I've always been a fan of the Ka-Bar. I've always been a fan of Randall knives. Those have really kind of inspired me a lot in my designs. So I kind of wanted to see what would happen if I put the two together and made my own... to put my own spin on it, you know. That's... with the straight clip, which is longer than you would see on a Randall since, you know, it is my design. It's my design style.

I wanted to go full tang, of course, because I do feel that—and this is just personal, it'll probably cause some guff in the industry and in the community—but I feel that that is, can be a weak point of the traditional Ka-Bar. That's why they came out with the slabby. They saw that and they wanted to—not necessarily fix it, but address it. So I wanted to go with the full tang design, which makes it incredibly tough, incredibly wear resistant, and resistant to damage.

Um, and I just kind of put my spin on it. The blade is about the same width overall as the Ka-Bar, maybe just a little bit wider. But I really just kind of wanted to take some of the overall dimensions and designs of the Ka-Bar and make it my own. So there was quite a bit of inspiration there, kind of like a launching point, a starting point. But I was able to really put my own stamp on it and envision my take on what a combat utility should be.

[07:45] Bob DeMarco: It seems like it also has—I don't have a Ka-Bar in front of me—but it seems like it also has a thicker blade stock overall.

[07:52] Calvin Richardson: Uh, yeah. We went... I can't remember what the Ka-Bar is, but we went with 3/16ths. I believe it's metric, so it's just a little bit over 3/16ths. I can't remember exactly what the stock is, but it's right around 0.186 thick. So, in my mind, unless you're creating a knife that's just an absolute tank chopping monster, you really don't need much more over 3/16ths. It's a perfect blend of speed, versatility, and toughness. It just... plus, to be very blunt, if you do have to use it in a self-defense application and a thrust, the 3/16ths is going to work far easier than a quarter inch. Quarter inch is going to get hung up and cause problems.

[08:40] Bob DeMarco: So outstanding field knife. I've put this through my suburban dad paces in the backyard near the fire pit. So let me just preface it by saying that. But really excellent field knife. But I picked this up and I want to do my Kali flow drills with it because it is, you know, obviously you've taken into account that this could be used as a weapon as well. And in my personal taste in knife collecting and knives in general, that resonates with me a lot. So in light of that, why did you go with the clip point?

[09:15] Calvin Richardson: [Laughs] I have been in love with the clip point ever since I was little. Bowies have been a huge, huge thing for me. In fact, when I first started making knives, I wanted a big Bowie and I couldn't afford one. I was unemployed at the time. So I thought, well, what the heck, I'll just make one. And I made about an 11 and a half inch Bowie. It wasn't the nicest. It was pretty good. But I've just always had an absolute fascination with them. I feel that they fill that combat utility role really well. You know, the reinforced point that you get with a straight clip. And I feel that the straight clip is a little bit better for that because when you have a radius clip, at some point in time when you get out towards the tip, it becomes finer and finer and finer. Whereas with a straight clip, you've just got a straight plane to absorb the shock.

But the Bowie also allows for a more aggressive point, and it puts the point lower than the spine, obviously, since it's clipped. It puts that point lower than the spine and puts it more on the centerline of the knife. Which again is one of my goals with this knife. Um, I've just always been known for my Bowies. My Bowies and my fighters. Either a drop point fighter or a clip point fighter. And it's just, I don't know, something with it just resonates in my soul.

[10:45] Bob DeMarco: Uh, so I was trolling around on your Instagram page and man, the fighters that you make are really compelling to me. They look beautiful. They also look, uh, you know, like cousins, spiritual cousins of the Steadfast. You can see your design DNA in it, in them. But they're these long slender—again, sort of that long slender profile with a pronounced clip. Almost bayonet grind on a couple of them that I saw. So fighters also... like, how would you define a fighter as opposed to a Bowie?

[11:20] Calvin Richardson: Well, obviously... Bowie is has become kind of a catch-all term for a large part in the industry. I feel it's more specific to a clip point blade. A fighter is more over-arcing. It can be more of an umbrella term. It can capture a lot more blade shapes. Bowie to me is more specific in blade shape. Fighter is more... I find that defined more in the intention of the knife. It's not a heavy chopper. It's something that's balanced neutrally to be very quick in the hand, very light, very snappy. It does have a dropped point and radius to the spine so that you do get that snap cut. You do get that lowered tip that's in center with the knife.

Um, it just... it's... it's designed for the cut, but it's also designed for the thrust for a fighter, in my opinion. It has to be very capable of doing both. I feel like the Steadfast is a very good example of that. My Verres, my hog hunting knife, is an excellent example of that. And my Phalanx is another excellent example of those attributes, those things that I look for in a fighting knife.

[12:35] Bob DeMarco: So those are custom knives that we're talking about. Was the Steadfast, before Work Tuff started making that, was that one of your custom models or did you design that specifically for Work Tuff Gear?

[12:48] Calvin Richardson: No, that was a custom model. Um, in fact, a good friend of mine has the very first one. He... it's... I've done four or five of them. And then Vic [Zic] Menacho is a really good friend of mine and he'd been trying to put Vic and I together for a couple of years. And we were finally able to coordinate, come together and agree on the Steadfast design. It was kind of an area of the market, an area of their lineup, their catalog that wasn't real strong. So we felt like it was an opportunity to do something special, capture something special.

[13:25] Bob DeMarco: Yeah, actually now that you mention it, it is a nice middle ground for them because they have all these massive... I love their knives. I have, I guess I have only three of them, but I plan on changing that. They have a lot of massive work knives, chopping knives. I mean, you know, one could fight with them for sure, but they though they look aggressive, they're more, um, like the Puzon Predator Hunter, for instance. Like that's a big giant knife. And yeah, it would be scary to come up against someone with that. But it's more of a chopper, more of a big outdoor robust knife. And then they have numerous small little... they have a Nessmuk, I think, and small sort of working knives. But no sort of mid-ground combat knives, I feel. Or, you know, they do, I guess they have the Little Fighter and stuff like that. But this one really does seem to step into a gap that they have in their catalog.

[14:20] Calvin Richardson: Yeah, it... I don't want to say that there are any gaps in their catalog because they cover so much stuff. But... and I'm not saying that my designs aren't outdoor applicable, you know, that they can't be used in the outdoors because they can be very well. But my knives are not choppers at all. They are designed to be nimble and fast. Fast recovery. It is more of a combat area for Work Tuff to go into. And I thank Vic and I applaud him for having the sight to be able to notice that and step in and put this design into that category for them.

[14:55] Bob DeMarco: I want to talk about Work Tuff Gear and working with them and what that was like. But before we do, you know, you've mentioned a lot about snap cuts and thrusting and it makes me wonder, what's your background?

[15:10] Calvin Richardson: [Laughs] I really don't have one! I'm just a guy, a nerd that that studies a lot and reads a lot. And I think I put a lot of thought into my designs as I'm designing them. There's almost a meditative flow state that I enter when I'm designing a knife. And then when it's being prototyped, I'm constantly handling it, checking the balance, see what the ergonomics are like, figuring out what it...

[15:40] Bob DeMarco: So, what how do you go about designing them? Can you enter that flow state on the computer or are you drawing by hand?

[15:50] Calvin Richardson: Oh, it's all pen and—or pencil and paper. Everything gets drawn out to size. And in fact, I can go get my sketchbook if you want. And I can kind of show you...

[16:05] Bob DeMarco: Maybe, maybe we'll take a look at it for the Patreon extra. We're going to do an extra interview and that's a good teaser. Come become a patron so you can check this out. I love by the way... I went to art school, just as a side note, and I also like to draw, especially knives these days. But I love looking through people's sketchbooks. Just, no matter what it is, what they're drawing. I love that. So yeah, we'll check that out.

[16:30] Calvin Richardson: Okay. The funny thing is, a knife is the only thing I can draw. I'm not good at anything else. I'm very specialized in my art ability.

[16:40] Bob DeMarco: You're not the first person to say that. And it's amazing, when you look at the design by someone such as yourself who draws a lot of knives... you know, I look at that and I say, "Well, with the ability they have to control the pencil and draw this, they could probably do anything." You know, with the practice.

[17:00] Calvin Richardson: It's uh... it's therapeutic for me. It definitely... I haven't done very much of it. I just haven't had the time lately. But it's one of those things where it is meditative. It is very much therapy for me. Knife making is as well. Because I enter that same meditative Zen flow state and everything just kind of falls away and falls to the side. And I just get to exist and be... have one concern on my mind and that's it. It's wonderful.

[17:35] Bob DeMarco: Okay. So you draw up the Steadfast. You know... so how does that work with Vic? I know his name is Vic, the gentleman who owns and runs it. You send him the design and is there a back and forth? And then how does it become reality?

[17:52] Calvin Richardson: So Vic is really, really easy to work with. He wants his knives that he produces to be a almost an exact copy of like what the custom would be. He wants the designer's... I don't want to say aura... but he wants the designer's stamp and hands all over the design. So basically I drew the design up, I gave him some scales. Like: "This is how long it is. This is the blade length. This is how tall it is." Gave him some basic dimensions. And then he converted that hand-drawn picture into CAD. So it is basically a direct representation of the design. There isn't any... what I designed is what you get. There's no compromises. There's no stepping around what it is.

And then with the handle scales, we had some problems getting everything dialed in. So what I ended up doing was actually shipping him the handle scales to Taiwan. And he took those handle scales, pulled his dimensions off of it and went from there. There are still some slight differences between what you would get in my custom as far as ergonomics go and what the production model is. But that's solely for the reason that a lot of the things that you would get on a custom are just really difficult to reproduce on a production model. You know, there's a lot more time that can be put on a custom. That's what you're paying for. You're paying for knowledge, time, and experience when you purchase a custom. And I'm not... I'm not saying anything bad about what Vic does. He is amazing. His team is amazing. There are just some slight differences between production and custom.

[19:55] Bob DeMarco: Yeah. I mean, just by necessity and just by the nature of the thing. But you do see, when you visit the Work Tuff Gear Instagram page, you do see people hand sanding the backs and... really, a lot of hand work goes into these. A lot of special attention to each model. They don't do giant runs of things. So that's something that I like about Work Tuff Gear in general. It feels like you're kind of getting a custom knife. You know, that it didn't just pop out of a machine.

[20:30] Calvin Richardson: Yeah. There is a term in the knife industry called "Mid-Tech." It's where a custom maker has blanks mass produced. He might have them ground. He has them hardened, batch hardened. It's not a one-off custom. And he might have the handles CNC'd. But then he goes in and he finishes them himself. He'll assemble them. He'll make sure... he'll do all the QC work. He'll sharpen them by hand. He'll do all of that stuff. And that is exactly what Vic and his team do. They're not... more or less a production shop like you would get with Benchmade where everything's done by predominantly robots or machine done. You get a lot of that hand fitting. You get a lot of that Mid-Tech custom work. And that was another reason I wanted to work with them. Just because they are able to produce a designer's designs in such a way that the highest quality is presented. I put them up against anybody. Their work is phenomenal.

[21:40] Bob DeMarco: Always razor sharp and always super tough. At least with the three I have and the two others I've handled. They're amazing. The one place I feel Work Tuff falls short... and I don't want to even say they fall short, they actually overdo it. Their sheaths are so good and hold the blades so well. They're always a little big for me. And I always... certain knives to me deserve leather. And this knife I would love to have a leather sheath made just because, to me, leather is a more appealing material. On scale it's not as easy to work with. And these, you know, the goal of making these knives is to have something... it's in the name. Something super tough. And there's nothing tougher than this kind of plastic or for sheaths.

But when you're working with them, do you get to choose the materials? This is in K329, which I was unfamiliar with before I got their brand. And seems to be a pretty awesome steel.

[22:50] Calvin Richardson: Yeah. The initial... I wanted to do it in SK85. And then Vic came to me and was like, "Hey, we're going to start using this new steel. It's called K329 by Bohler. A new Bohler." We kind of talked back and forth about it and the properties of the knife and we both agreed that it would be the perfect steel to use for the Steadfast. You know, it's just a phenomenal steel. It's super tough. It's got better corrosion resistance than SK85 does, which is just a plain carbon steel. Japanese plain carbon steel. So there aren't very many alloying properties in it. But K329 is just as tough as nails and takes a screaming edge. Absolutely screaming edge that Vic and his team do.

[23:45] Bob DeMarco: Yeah, and it's slightly convexed. Or convexed at the very, very edge. And I love that too. I love that too. Because you get... it's not the whole bevel isn't convex, just the edge. And man, it gets so sharp and it's so robust too.

[24:05] Calvin Richardson: Yeah. And the funny thing is that's exactly how I do my customs. They're predominantly flat ground. I'll take them down to 15 to 20 thousands thick before I sharpen them. And then they're sharpened at 80 grit to form the edge bevel. And then I come back with a 400 J-Flex, which is a very soft, very pliable belt. It's a cloth belt as opposed to something stiffer. And I'll go into the slack portion of my belt and I will finish grind that. And give it that convex edge. And Vic does the exact same edge on his blades, which I just absolutely love. That convex gives you enough meat behind the edge, but still a fine enough edge that it'll just... it'll last for days. It's just awesome stuff.

[24:55] Bob DeMarco: So from the designer's perspective of the Steadfast and the Steadfast Large... I have to ask you because I'm gonna buy a Steadfast Large. And I like I said... I think I have a bead on one. And I'll say it, I think DLT has one. And I'm saying that now because I will have purchased it before this episode drops. So I'll feel free. And it also has the white liners like mine. And they also have a dark wash version which I like, but I think I'm gonna go matchy-matchy, you know, with my Steadfast. To you, as the designer, what are the differences besides an inch and a half in blade length? Between the knives in terms of performance and spirit?

[25:40] Calvin Richardson: The 7-inch is much more... much more combat oriented. It is not a chopper at all. It is extremely neutrally balanced. The balance point is literally right here. You can balance the knife... see if I can do this without dropping it on my foot and having it go into the floor... you can balance the knife right there behind the guard. And it just makes it... for lack of a better term, it is a combat knife. The five and a half inch regular Steadfast is just a touch butt heavy. You put some custom scales on it by Carol's Custom Scales, which... he does custom scales for both of these. They have the exact same handle between the Steadfast and the Steadfast L. It is exactly the same. But you get some custom scales for the regular Steadfast and it lightens it to the tip because he does a lot of Micarta which is lighter than G10. It takes that balance and transfers it more to the tip. It makes it a little bit more neutrally balanced.

But this has so much... you wouldn't think an inch and a half would change that much. It's got so much more reach. It's got so much more neutral balancing for speed. Which I have no idea what I'm doing, but I like to wave the knife around.

[27:10] Bob DeMarco: It gives the air of knowing what I'm doing, right?

[27:12] Calvin Richardson: It just completely changes the characteristics and the dynamics of the knife. It really does.

[27:20] Bob DeMarco: Yeah, and that is where you balance a fighting knife. Right there at the forefinger, at the guard. And so I guess that'll... so if you were going out in the woods, you might prefer this over that because this is more of a field knife, I guess.

[27:38] Calvin Richardson: Uh, a little bit. A little bit. Like I said, you can still take the L and do field knife applications with it. My son dressed out his... yeah, he dressed out his deer. Split the rib cage. Went down through it. Did everything with it. Got inside and cut the connective tissue loose. That might be a little gory for some folks to hear. I apologize for that. But he did absolutely everything he needed to to field dress that knife with the L and it worked wonderfully. Worked wonderfully. And it still shaved after he got done.

[28:10] Bob DeMarco: So are you thinking of working more with Work Tuff Gear? Would you like to bring another design their way?

[28:18] Calvin Richardson: I would love to. I would really like to do my Verres which is Latin for Boar. My Boar knife with them. Again, it's... I'm not... I really kind of shoehorned myself in my designs. I don't do very much outdoor stuff. I do a small drop point Orca which is designed for Whitetail hunting. Especially here in Missouri with the size animals we get. I don't do very many outdoor designs. Most of my stuff is focused primarily on fighting. It's... yeah. That Verres, I designed it for Boar hunting. I've got a buddy that's mildly insane. And he hunts... he hunts Boar with nothing but a knife. The dogs hold him by the ears and then you slide up the back and you use the knife. Uh, he might be a little more than mildly insane. He's a little crazy. But I designed the knife for that. So it's obviously got very tactical combat overtones to it as well. But we'll see what Vic wants to do. I know he's incredibly busy right now. He's just got so much going on. And his stable of designers has gotten so large. You know, he's really got to kind of schedule stuff out and figure out when and where he's going to do what.

[29:50] Bob DeMarco: And I'm sure for him, he needs to be sure to maintain the spirit of Work Tuff Gear in being that sort of Mid-Tech shop and being that sort of very hands on. I know that he doesn't have a huge crew of people working for him. And I'm sure that that's a large selling point for his work. So yeah, he's got to...

[30:10] Calvin Richardson: Yeah, I think there's only five in their shop total.

[30:13] Bob DeMarco: Wow. Unreal.

[30:15] Calvin Richardson: And they're able to put out the numbers that they do and maintain that quality.

[30:20] Bob DeMarco: So the Verres, you were just talking about... I got a look at that. That beautiful long slender... looks kind of like a spear point with a very long swedge. And a nice comfy looking handle. I mean that knife looks beautiful. And so tell me about your handmade knives and the process you go through to make that. You mentioned you get in that flow state while making them. How do you do it?

[30:50] Calvin Richardson: How do I enter that flow state? Or how do I just do it overall?

[30:54] Bob DeMarco: Yeah.

[30:55] Calvin Richardson: Okay. It starts out with the design phase. Everything is designed exactly to scale. So if I'm looking for a 5-inch blade and a 5-inch handle, I draw out a 5-inch blade and a 5-inch handle. Everything is exactly to scale. I base it... I've got a very normal sized hand. My palm is a little wide. I figure if it'll fit my hand, it'll fit 90 to 95 percent of people's hands out there. So I design it according to the width of my hand. Which is very generic. And I go from there. I design everything out. And then I take that design and make a photocopy. I transfer it to... I glue it down to a piece of Kydex. Which gives my pattern rigidity and integrity. I don't have to worry about it degrading over years of tracing around it. I am a stock removal maker. So that means I take that design, I transfer it to my steel. I put layout dye on my steel and I trace around the pattern to get my outline. And then that gets cut out. It gets ground to size. And then from there I start figuring out where I want it to balance, how I want it to balance. I'll remove some material from the tang of the handle to get a little bit more tip heavy. I've done it long enough that even before I start grinding, I kind of know how I need it to balance in order to get the handling characteristics I'm looking for.

I've been doing it for 14 years. Over 14 years. Almost 15 coming up in March. Either March or May. I can't remember. One of those M months. But I kind of know how I want it to balance before I even start grinding on it. It gets sent out for heat treat. I've started moving into more stainless steels that I need to have heat treated outside of a shop because I don't have an oven. I've moved into Nitro-V and CPM-154 almost exclusively. And I feel that those steels are just... they're awesome. Especially Nitro-V. It has so many... so many benefits. It's just silly not to use it. And it takes an absolutely screaming edge.

But they get sent out to heat treat. I get them back. I lay out my edge thickness with a height gauge. A dial height gauge. So I scribe... I'm going to have to be careful not to cut myself. I don't know how well you can see this. But I go down the middle of the blade and I scribe... like say I want 10 thousands. I'll do the math and I'll figure out how far down I need to go on each side to get that 10 thousands edge geometry. I'll scribe that out. And then I grind that to that edge thickness. And then everything from there is hand grinding and... I don't use any kind of jigs. I don't use any kind of rests. Everything is completely hand ground. And by freehand ground, and by that I mean... I hold it up against the grinder like this and I grind that edge. It's just how I do... how I've always done it. I don't use a file guide to get my plunges right. Because that throws off the balance of the knife and will make me go in hard in one spot and dig into the blade. I've done it long enough and enough that I can get them as close to perfect as I possibly can.

So everything gets ground by hand. Then the scales get glued up. You know, they get rough cut to size. They get glued up. They get fastened. And then it's a matter of shaping them on hand on the grinder. And figuring out where I want the balance to be. And I can manipulate the scales, thin them in here a little bit if I need to move the weight towards the tip. If it's a little butt heavy. It's just... it's all a matter of compromising. You know, you've got to find that sweet spot.

[34:45] Bob DeMarco: That's cool you were talking about getting the behind-the-edge measurement just right. I've seen many people, you know when I'm watching knife making videos, how they'll have the dye on the... not the spine but the belly of the blade before it's sharpened. And you'll see two scribe lines. And that must be what you're talking about. They've measured it out. But I never knew, until right now it just dawned on me because you explained it, why the two scribe lines. I was always thinking shouldn't there just be one because they should meet in the center? But yeah, if you're conscientious at all about your behind the edge thickness, you do need those two lines.

[35:25] Calvin Richardson: Yeah, yeah. You can... you need at least those two. You can do three. I have found once you get down to like say 20 to 10 thousands edge, which all my kitchen stuff gets a 10 thousands grind before I put the edge on it. It makes for just an absolute laser cutter. But if you put all three in there, it becomes kind of cluttered. It becomes difficult to see where you're grinding to and where you need to stop. But that's that's why you put those two lines on there. If you did just one down the center and that's what you ground to, you would end up with a zero grind blade which would be incredibly sharp. Just insanely sharp, but it would have no integrity. It would chip, it would roll, it would dent. You would have no strength behind the edge.

[36:15] Bob DeMarco: So you just mentioned that you've gone pretty much exclusively to Nitro-V and 154CM. You said in particular that Nitro-V... CPM 154. Big difference between CPM 154 and 154CM. Sorry. It's just ones a Crucible powdered steel. Yeah, yeah, yeah. Sorry about that. In terms of... well, actually you can answer this on both steels. You mentioned Nitro-V has like all of these really amazing benefits. What are they and are they benefits to you in the making or do you mean as a great user steel?

[36:55] Calvin Richardson: It's kind of both. So, before I started using Nitro-V I had used CPM 154 some. But I was primarily a carbon steel maker. You know, that's what I had access to heat treat. That's what I did. And carbon steel, especially 52100 with the right heat treat, is very easy to grind. It just kind of flows off. And Nitro-V for a maker in that 60 to 61 RC area... like 59 to 61 hardness range. It grinds like butter. And I'm fortunate enough to consider to have as a very dear and close friend one of the collaborators on the steel chemistry for Nitro-V. And he's actually the one that does a lot of my heat treat for me. So he knows the steel infinitely. He knows exactly what he's doing with it. Just a phenomenally intelligent person.

But I find that the more I use Nitro-V, the more I prefer it over CPM 154. It's a little bit tougher. It's easier to grind. It's more forgiving. It's just... if that was the only steel that I had to offer, I would be fully comfortable and confident in my offerings with that. It's just a phenomenal steel.

[38:25] Bob DeMarco: I know we've seen quite a bit of Nitro-V over the last couple of years in a lot of production folders. And it's not... it's not a budget steel and it's not a super steel, you know that they can charge a premium for. But it just seems to be an everyday awesome user steel. I'm also a big fan of 154. For me, I think it's mostly CM. The ingot steel I guess. I love 154 for its edge and for its ease of sharpening and for its... you know, it does keep going. It keeps its edge well and... what are your feelings on 154?

[39:10] Calvin Richardson: I love 154. Like I said, that was my only stainless experience until I got Nitro-V. The type of edge... you know there are a lot of steels anymore like with S90V and some of the crazier super steels. You think of like M4 tool steel on some of them. Their edge holding characteristics are just insane. The problem you run into with that is a difficulty of sharpening. Because if it'll hold an edge forever, it'll take forever to put an edge back on it. So CPM 154 and 154CM I feel are really a good compromise. I look at knife making as a game of compromises. You know, you take a little bit here to add a little bit here. And you try to find that middle, that sweet spot. You do it with your edge geometry. I'm going to have a compromise here based on what the design, what the focus of the point of the knife is on. So like a kitchen knife, you use... you compromise for a finer edge. Well that means you don't necessarily have as much edge integrity. You know, it'll chip, it'll roll easier.

You do the same thing with your steels. So that's where I find Nitro-V and 154 really fall into a nice compromise area. It's easy to maintain the edge. It's easy to put an insanely sharp edge on it. It's a nice compromise of strength and a nice compromise of hardness. You know, you don't have too much of one or the other. It's just... they're just great middle ground steels that everybody can use.

[41:00] Bob DeMarco: They're also both, in my experience, nicely corrosion resistant. Especially on a sweaty hot Virginia day, you know, you come back in and you don't have to be sanding your knife down.

[41:12] Calvin Richardson: Yeah. And I tell you what, Missouri gets pretty rough too. It gets... our summers... we get the worst of it. We get bad summers and bad winters. Nice and soupy. Oh my gosh. It'll be 105 outside with like 85 percent humidity. It's terrible.

[41:30] Bob DeMarco: So you've mentioned a couple of times that you make kitchen knives. How much a part of your custom knife making business does kitchen knives take up? And what are the challenges in making them?

[41:45] Calvin Richardson: It's not very much because frankly I hate making them. [Laughs] You have to be so careful with them because the edge geometry is so fine and you're already dealing with a thinner steel. A 90 thousands... I do all my kitchen knives out of 90 thousands. Out of 3/32 stock. Oversized it comes out to like 110 thousands. So less than an eighth of an inch. You have no thermal mass there. You have nothing to soak up the heat from the grinding, from the friction. So you have to be very, very careful especially when you're getting down to that 10 thousands before you sharpen the edge. You have to be very, very careful with how fast you're running, the kind of pressure you're applying. Things like that. And they are just absolute thumb scorchers. Like I said, I grind completely freehand with no jigs. So I can tell with my thumb how hot I'm getting the steel. If it'll fry my thumb, I'm getting too hot.

So as you go out towards the tip, you're getting thinner and thinner and thinner and thinner. And you have to apply pressure more directly because the edge will actually flex away. So they're just... they're very technically challenging knives to make. They're very physically challenging knives to make. And they are, in my opinion, they are the epitome of the cutting arts. You know, you're creating something that will hold an edge for a long time, take an extremely sharp edge and an extremely fine edge. And it's just... they're very difficult to make. Fillet knives are the absolute worst. Fillet knives. I can imagine. Because that's got to flex. It's got to flex without breaking. It's got to be very, very, very sharp. So you're getting... you're getting real close to the other side I would imagine as you're grinding.

[43:50] Calvin Richardson: Yeah. And they have an extremely fine tip and you have to apply pressure all the way out to the very end of the tip because again, like you said, they're flexible so they want to flex away from the grinding belt as you're applying pressure. So you have to keep pressure with your thumb or a stick if you're using a jig. You have to keep pressure all the way to the tip. It's just... I hate them.

[44:10] Bob DeMarco: Well, I have a respect for custom kitchen knives. I have a gigantic collection of Bowies and fighting knives and all sorts of stuff I never use, you know. But I use kitchen knives every day. My wife and I both love cooking. And, you know, whether we love it or not we still have to live so we're cooking, you know, every day. So using these knives every day... we have we now have two custom chefs knives and one paring knife. All from the same maker. I love them. But lately my eye has been wandering. Not from the Bowies to the kitchen knives, but adding kitchen knives to things I need to acquire. So I'm... and I bought one for my sister for Christmas that she's giving to a friend. And just to have a custom knife for the kitchen that you know is going to be used every day. It's just a great... a great thing. I don't know. I don't know where I'm going with this, but I want more.

[45:15] Calvin Richardson: Yeah, it's one of those things. I find for me personally kitchen knives are the epitome of knife making because they are a knife that is going to be used every day. Sometimes multiple times a day. So you absolutely have to be dialed in on your steel choice, your heat treat, your grinds, your balance. The shape of the blade. You know, I prefer a rolling cut so all of my kitchen knives have a continuous radius across the bottom edge. They will not flatten out. They will not thump into something. They will cut all the way from the tip to the heel. It is one of the few areas where we have a justified use for using a knife every day. Justified reason for using a knife every day. And there are folks out there that use them all day. And so they have this wealth of feedback and knowledge as to what they want and what they need. It's just... it's an entirely different world. And any maker that is really good at that... you know I think of Jordan Berthelot. I think of Nick Rossi. Some of my other friends that are... Don Nguyen. I think of some of those guys that focus a lot on kitchen knives. They are just incredible makers.

[46:40] Bob DeMarco: Okay. So we understand kitchen knives are a huge challenge. Are there any knives in your handmade, custom handmade knife pursuit that you have not tackled yet that you want to? Something challenging or something from history that you love. Just something that you want to make in the future that you haven't yet? What would that be?

[47:00] Calvin Richardson: It would probably be... the one that's been keeping me up at nights lately is the MacV SOG Bowies. Those and the Mark 3 Fighting Knives. I had a... my maternal grandfather was in World War II and he was part of a group called Merrill's Marauders. They were a volunteer group that went into Burma and saw some of the heaviest action of World War II. They fought with the Chinese against the Japanese. And because they were a volunteer group, their supplies and their support was non-existent. So what I would like to do... I've got a design for it. I want to do a, my take on a Mark 3 Fighting Knife because that was what he carried. They carried predominantly kukris or Mark 3 Fighting Knives. And I would like to do something like that for him. So yeah, the MacV SOG Bowie or the Mark 3 Fighting Knife. Again, staying in my lane with fighters.

[48:15] Bob DeMarco: I love that. So just everyone probably knows the MacV SOG. It's that double peaked spine Bowie knife that, you know, I guess really came out in the early part of Vietnam and persists today. But remind us of the Mark 3 Fighting Knife.

[48:35] Calvin Richardson: So it's almost like a bayonet shaped blade. It came out I believe in the latter part of World War I into World War II. It's a thin, narrow, about a 6-inch blade with a bayonet grind on it. Its sole purpose is for penetration. It's for the thrust. The design that I've got for it has a little bit longer blade. I think it's like a 7 to 7 and a half inch blade with a dropped handle. Again, so in like a saber grip, that tip is right in line with your wrist and your forearm to support the thrust and really make the thrust more substantial. It is not a cutting knife. It is not a... anything other than a pure thrusting blade. It's all fight. All aggression.

[49:30] Bob DeMarco: So the one that your grandfather carried probably had a stacked leather handle? That sort of coke bottle shape? And that knife is from stem to stern pretty straight. Are you saying that your version of it has that that constant radius that you were talking about earlier?

[49:50] Calvin Richardson: So the blade is straight. And then once you get right behind the guard, it has some drop to it. And it's... if you've seen my Verres, if you've seen the Steadfast, it has kind of that same swelled handle to it. Where it's thinner right behind the guard and it swells for the middle of the palm and the middle fingers which are longer. And then it tapers back into the pinky area so that you can really grip down on it and really secure it in the hand. But it's got more drop to the handle. So the blade is straight and then there's a drop to the handle to put everything in line on a thrust.

[50:30] Bob DeMarco: So I guess if you were going to take it all the way to its logical end, a kukri should probably also be in your future. Because talk about a massive curve. And you can still thrust with a kukri almost in a more natural way than with something super straight.

[50:50] Calvin Richardson: Yeah, yeah. And that it's kind of the same idea behind the drop in my handles. It puts things... you run into issues with a kukri with penetration because of the way the blade flares to the middle point. I used to do a knife and if you look up my old Facebook page, Calvin Richardson Knives, you will find a knife in there that I called the Bone Cutter. It was my take on a kukri. It was... I couldn't ever get... you know the kukri comes up and the back breaks down and then you have the flared blade towards the tip. I never could get that geometry right. Just as a designer I couldn't get it done. So mine has a radius from tip to tail across the entire top. And then a flared edge towards a belly. I started doing them in like, oh when was it? 2012? Something like that, I think is when I came out with the first one. They're a pretty radical design. I might revisit that and redesign some things now that my design style has changed some and refined.

[51:55] Bob DeMarco: Well, we'll keep our eyes open. I know for for one I will. Tell everyone how they can follow you, follow your work, possibly get in touch with you if they want to order something. Tell 'em the best way.

[52:10] Calvin Richardson: Well right now my shop is closed down indefinitely because I no longer have a place for my equipment. So it's sitting in storage right now. So once I can find a place that has a shop area I'll be back up and running. But if you want to follow my work you can find me on Instagram at @calvinrichardson.1981. You can find me on Facebook under Calvin Richardson Custom or it's facebook.com/makingsteeldust. And you can message me on either of those platforms. I'm more than happy to talk knives. If you have an idea for a project, we can talk about that. You know, I do some one-off stuff for people. I've got a kukri design that I'm doing for a friend and once that knife is done it'll never be made again. So there is some very exclusive, limited stuff that I do. So yeah, if you want to get a hold of me those are the two best ways to get a hold of me.

[53:15] Bob DeMarco: And then of course keep your eyes peeled for subsequent releases of the Steadfast. I know this is from the second release. And then the third release is the Large. And like I said, I will be getting one of those post haste because I think there's only two that I've been able to find and one of them matches my first one. So well, Calvin, thank you so much for your time and talking all about your your designs. And so that people know, if you're a patron we're going to continue this conversation and Calvin's gonna bust out his sketchbook and show off a couple of sketches which I'm really looking forward to. Thank you so much for coming on the show, Calvin.

[53:50] Calvin Richardson: Thank you for having me, Bob. It was a pleasure.

[54:00] Announcer: Want to sell your custom knives online? With Launch Cart, you can easily create your own e-commerce store. No coding required. Launch Cart is designed for knife makers like you. With built-in tools to showcase your craftsmanship, manage orders, and grow your brand. It's fast, flexible, and even includes low cost payment processing to help you keep more of your profits. Start your online knife store today at theknifejunkie.com/launch and turn your passion into a business.

[54:30] Bob DeMarco: There he goes ladies and gentlemen, Calvin Richardson of Calvin Richardson Custom Knives. Be sure to follow him on Instagram for some serious knife eye candy. And also Work Tuff Gear, follow them so you can watch his production work drop and get your hands on some. All right for Jim working his magic behind the switcher, I'm Bob DeMarco saying until next time, don't take dull for an answer.

[54:55] Announcer: Thanks for listening to the Knife Junkie Podcast. If you enjoyed the show, please rate and review at https://www.google.com/reviewthepodcast.com. For show notes for today's episode, additional resources and to listen to past episodes, visit our website theknifejunkie.com. You can also watch our latest videos on YouTube at theknifejunkie.com/youtube.

Share This With a Friend >>>

For early access to The Knife Junkie podcasts and YouTube videos, receive Knife Junkie stickers and be entered into the monthly knife drawing giveaway, join The Knife Junkie’s Patreon group of awesome supporters.

Let us know what you thought about this episode. Please leave a rating and/or a review in whatever podcast player app you’re listening to. Your feedback is much appreciated. Email theknifejunkie@gmail.com with any comments, feedback, or suggestions on the show, and let us know who you’d like to hear interviewed on an upcoming edition of The Knife Junkie Podcast.

To listen to past episodes of the podcast, visit theknifejunkie.com/listen.

Shopping for a Knife?

Support The Knife Junkie Podcast and YouTube Channel by Buying Through My Affiliate Links

Angle Pro Knife Sharpener

Artisan Cutlery

Bamba Forge

Civivi Knives

eBay

Jack Wolf Knives

James Brand

Knives Ship Free

Off-Grid Knives

Sencut

Smoky Mountain Knife Works

Tiger Edge

T.Kell Knives (Get 10% OFF with coupon code: “knifejunkie”)

Vosteed Knives

WE Knives

Other Products and Services

1Password

16-in-1 Multipliers

Dark Age Defense

Podcast Hosting

Groove (Replace 17 Apps and Services in Your Business)

Groove.ai (All-in-one AI solution)

Knife Books

Rakuten (Cash Back for Shopping Purchases)

Shockwave Tactical Torch

StreamYard

Upside App (Cash Back for Gas Purchases)

SOS Emergency Sleeping Bag

Survival Saw

Wilderness Survival Skills Course

Work Sharp

Work Sharp Rolling Knife Sharpener

“The Essential Skills of Wilderness Survival” Book

Follow The Knife Junkie

Visit The Knife Junkie website

Email The Knife Junkie

Follow The Knife Junkie on YouTube

Follow The Knife Junkie on Instagram

Follow The Knife Junkie on Twitter

Join The Knife Junkie Facebook Group

Affiliate Disclosure

In the name of full transparency, please be aware that this website contains affiliate links, and any purchases made through such links will result in a small commission for The Knife Junkie channel (at no extra cost to you). If you use these links to make a purchase, TKJ will be rewarded with credit or a small commission on the sale. If you don’t want to use these links, no problem. But know that I truly do appreciate your support.