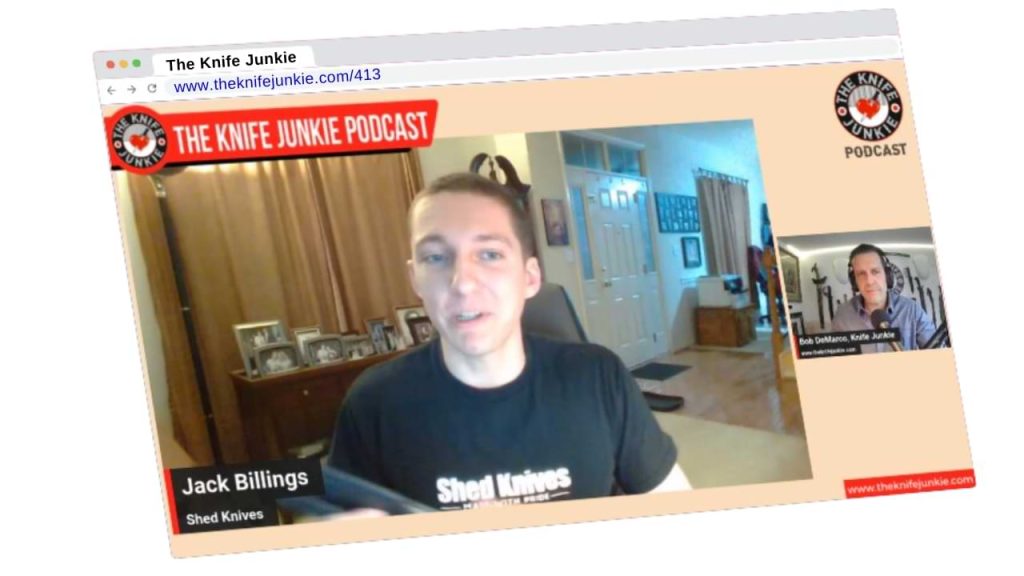

Shed Knives – The Knife Junkie Podcast (Episode 413)

Jack Billings of Shed Knives joins Bob “The Knife Junkie” DeMarco on Episode 413 of The Knife Junkie Podcast.

Originally started in 2018 as just a hobby, Shed Knives was started by three friends making knives on Saturday mornings. Its first knife was a sword — katana. In 2018, the three friends started trading knives for bigger and better machines to build the “Shed Knives Shop.” For $5 they made their first forge.

The three friends started making and selling their first knives which were named the 2019 Sheepsfoot, U.S. Tanto, Drop Point, and Wharncliffe. They started selling at scouting events, to friends, family, and whoever else wanted one.

In 2019, Jack was the only original member left, but he found new team members and was able to continue producing knives and fulfilling orders. After getting their feet wet with the business, 2020 was the first year with a clearly defined product release. That year they got 10 stores to start selling Shed Knives.

Their best seller – the “Skur” – was a happy accident, coming from an error in grinding a U.S. Tanto. Shed Knives is on a consistent quality improvement kick, from knife designs to shop layout and build process, and is now rapidly expanding.

Find Shed Knives online at www.shedknives.com, on Instagram at www.instagram.com/shed.knives and on Facebook at www.facebook.com/official.shed.knives.

Be sure to support The Knife Junkie and get in on the perks of being a Patron — including early access to the podcast and exclusive bonus content. You also can support the Knife Junkie channel with your next knife purchase. Find our affiliate links at theknifejunkie.com/knives.

Originally started in 2018 as just a hobby, Shed Knives was started by three friends making knives on Saturday mornings. Hear the story of Shed Knives on episode 413 of #theknifejunkie #podcast. Share on XShed Knives - The Knife Junkie Podcast (Episode 413)

The Knife Junkie Podcast is the place for knife newbies and knife junkies to learn about knives and knife collecting. Twice per week Bob DeMarco talks knives. Call the Listener Line at 724-466-4487; Visit https://theknifejunkie.com.

©2023, Bob DeMarco

The Knife Junkie Podcast

https://theknifejunkie.com

Announcer [00:00:00]:

Welcome to the Knife Junkie podcast, your weekly dose of knife news and information about knives and knife collecting. Here's your host, Bob the Knife Junkie. DeMarco.

Bob DeMarco [00:00:19]:

Welcome to the Knife Junkie Podcast. I'm Bob DeMarco. On this edition of the show, I'm speaking speaking with Jack Billings of Shed Knives. Like many new businesses, Shed Knives came of age during the pandemic, born out of a passion and the free time to develop it. In the few years since, shed has developed a catalog of knives and a bustling business. I've had the Shed Knives US Tonto 2023 model and can vouch for its impressive capabilities with carving batoning and feather sticking. And I made a couple of backyard usage videos with that knife, something I rarely do. If you need the proof, we'll find out how Shed got its start and what its plans are. But first, be sure to, like, comment, subscribe, hit the notification bell, and share the show with a friend. And as always, if you'd like to help support the show, you can do so on Patreon. Quickest way to do that is click the scan the QR code or go to theknifejunky.com patreon again. That's theknifejunkie.com patreon.

Announcer [00:01:20]:

Do you like the sound of the alphanumeric combinations? M 392, four P and 20 CV, but bristle at eight cr, 13 MOV, and A-U-S eight. You are a knife junkie. Probably worse.

Bob DeMarco [00:01:35]:

Hello, sir. How are you, Jack?

Jack Billings [00:01:37]:

Oh, I am doing great. How are you today?

Bob DeMarco [00:01:41]:

I'm doing well. I'm doing well. Thank you so much for coming on the Knife Junkie podcast. As I mentioned up front, you sent me the US Tonto 2023 model, and I opened it up, pulled it out of the box, and I was like, okay, this looks rough and ready. Let's see what it can do. I took it out back and in my way bashed on it and put it through its paces, and I was very impressed. Congratulations on an awesome knife and your company.

Jack Billings [00:02:14]:

Thank you. Well, I certainly appreciate it. A lot has gone into the 2023 collection, and I'm glad you got some great use out of it, like in the videos you posted. So definitely some great use there. And that's what I make them for.

Bob DeMarco [00:02:33]:

Awesome. All right, well, let's talk about how you got into knives in the first place and how you started this business.

Jack Billings [00:02:40]:

Yes, so I started making knives as a hobby in 2018, and it really came about. I was sitting on the couch watching some YouTube videos, and my friend Sam was there. We're just looking stuff up online, and he was like, oh, let's look up how to make knives. So we start watching some videos. We came across a YouTube channel that was making a forge, the king of random. And he was making a forge to melt aluminum cans. We were like, you know, that seems pretty easy to do at the time. I was 13, he was 14. And we're like, oh, let's do it. So we built our first forge on the very first try and then just started making knives after that. So really started from YouTube and the Internet and turned into a business from there.

Bob DeMarco [00:03:38]:

I love that. Your business. When you look at your website and when you look at the paperwork, you send in your packaging, it's very polished and it looks like it's very well developed. But I love hearing of the sort of raw beginnings. You said you made a forge and it was easy. I've made one of those number ten coffee can forges, and I did not have such an easy time. And I was way older than 13. Tell me about how you made that forge and then what did you use it for? Were you forging stuff out or did you just use that to heat treat?

Jack Billings [00:04:13]:

Yes. So let's see. To answer the first question, how I actually made it there. Well, I got a tin can roughly like maybe a four gallon tin can, slightly smaller than a five gallon bucket, but it was an aluminum can. And as you know, aluminum melts very fast. Well, there's a river by my house that has clay. So we were like, oh, let's just line the thing with clay. Stick a tin can in the center of it, drill a couple of holes in to get airflow, and so we can stick our sword in. Because the first project that we ever did was a sword. So I found a piece of metal in the woods and instead of making a knife or something like that, I was like, oh, let's just go straight to a sword. So made a sword, that was the very first thing, but for what I used it for, it started as just heating raw metal, pretty much, and then hammering it out. But because it is pretty loud, we were like, we can do this a better way. So I ended up using the forge just for heat treating, and that was really the majority of the use for it. It also burns stuff very fast. So really good way of just burning firewood, if I had any extra. But yeah, the forge really got a ton of use over the years.

Bob DeMarco [00:05:45]:

So as you're talking about this, it made me think, or it made me wonder. You and I are of different generations. I know what got me into knives besides my grandpa and stuff from very, very early age. It was the Rambo movies, it was the Arnold Schwarzenegger movies of the maybe a little bit of the 90s. From your perspective, you went straight to sword, and I love that, making a katana right out of the gate. What kind of culturally got you into knives?

Jack Billings [00:06:18]:

Yes. So really it was the Boy Scouts. That's what got me into it. I started as a Tiger Scout and worked all the way up to Boy Scouts. And I got my first knife, I believe, as a bear. So three or four years into the Scouting program. So then I started carrying a small little folder, just something cheap. If I lose it or break it, then no big deal. But I started carrying a knife then and really started getting into it by just small projects like Woodling making, tent steaks, just stuff like that. And then seeing the older Scouts, when I got into the actual Boy Scout program, seeing them carry fixed blades and larger knives, there is something cool with this. So then I started building my collection over the years. And yes, really, it was the Boy Scouts that really developed that passion. But I also get it from my dad. He has been a big knife collector for I don't know how long now, ever since he was in the Scouts as well. But he really helped grow that passion for knives as well.

Bob DeMarco [00:07:33]:

So what kind of skills did you pick up in the Boy Scouts and maybe from your father that you do with a knife that are invaluable?

Jack Billings [00:07:44]:

Yes, so a ton of stuff, really. Wilderness survival was a big one in the Boy Scout program. We would go to summer camp every year, and every year I took the same merit badge, wilderness survival, where you build a shelter, you use limited resources, and I absolutely love that. So that is something that they said, yeah, you get a knife and you get the outdoors. So build a shelter, get to it. And year after year, and outside of the camping, of course, on my own time, I kept refining those wilderness skills. And then also another part which really is very different compared to wilderness survival is sailing. I was a sailing instructor at Rodney Scout Reservation for a year, and a knife really came in handy because if you get tied up in some line on the boat, that can be really dangerous. So I always kept a knife right on my life jacket. There all sorts of uses that the program showed you can use a knife for.

Bob DeMarco [00:08:59]:

So how does that experience and now my curiosity is really piqued about the sailing bit, because your knives do not in any way strike me as floating. No, but it's interesting because we talk a lot on this show about outdoor camping survival usage, combat usage, self defense usage. And we have never, I don't think we've once spoken about it in a maritime context. We can see how some of that outdoor stuff goes into that. But tell me what goes into the design of these knives and how does that sailing bit work in?

Jack Billings [00:09:42]:

Yes, so the sailing bit that actually came in from someone I sent a knife to, it was weird. I designed my knives to be used primarily in a wilderness survival setting, in a bushcraft setting. But I sent a knife to a kayak fisherman, and this was in 2019. I sent him a knife, and it didn't have a lanyard hole, so he drill bit after drill bit. He Burke up, like, seven or eight of them and sent me a message. He's like, Jack, could you please put a lanyard hole in the knife? I cooked so many drill bits, like, oh, man, that's a good idea. So fast forward. I have a half inch lanyard hole in each knife, and I started doing that in 2021. Smaller holes were put in years before, but I decided the half inch lanyard hole works best because bringing up the sailing, the line is not like 550 cord. It's usually very thick. So having a half inch linear toll, you can get the thicker pieces of rope in there. And that way you drop your knife. Well, just pull the line in and you got your knife.

Bob DeMarco [00:10:58]:

Well, since it's in hand, let's see the knife that you've got right there.

Jack Billings [00:11:02]:

Yeah. So this right here, this is the 2023 Shed Knives Conquest. This knife, the design actually came out in 2021, and it actually came out, like, halfway through the year, where usually I just release the knives all at once. But this one here is very special. It's more of a self defense knife or everyday carry for a couple of different reasons. One, you have a tonto blade there, which is really helpful for an everyday carry because you have a point not just there, but also down there. So it helps with dulling the knife. Well, you have a backup point. Then. For the self defense part, you have this beautiful curve right there on the knife, where you have jimping there for your thumb so you can push into something. You also have a stop there for your finger, where not all knives in the 2023 line have that stop for your finger. Where this? Your hand is locked in. And also the curving on the handle here on the blank, it fits the hand really well, and it has a nice solid feel. So there's the 2023 shed knives conquest.

Bob DeMarco [00:12:20]:

Okay, that's cool. First of all, congratulations on that knife.

Jack Billings [00:12:26]:

That's a cool. Thank you.

Bob DeMarco [00:12:27]:

Very cool looking knife. My tastes definitely lean towards the tactical and the self defense and the combat.

Jack Billings [00:12:35]:

Yeah.

Bob DeMarco [00:12:36]:

And so, naturally, when I got the 2023 Tonto, I'm all feeling how it is in the Filipino grip with that jimping. Your jimping is awesome, by the way.

Jack Billings [00:12:47]:

Thank you.

Bob DeMarco [00:12:48]:

I like large jimping, and this is large, but this is more like medium jimping. Whereas atops, they're almost too big and too far spaced apart. Anyway, what I was getting at was, even though this is not that kind of knife, every knife can be that kind of knife. I tried it in this position and commented on one of the videos how I like that for hooking the thumb over the top.

Jack Billings [00:13:13]:

Yes.

Bob DeMarco [00:13:14]:

It looks like you have that in the Conquest.

Jack Billings [00:13:17]:

Yes. So the 2023 line has a bunch of similarities spread through all of the knives. And I'll pull out a few here just to show some of the similarities. So all of them have the same steel, same handle. They're all fairly similar in materials. All of them have that top is curved part on the very rear of the handle there. Top is curved, the bottom is a nice call. It like a soft point because it won't cut you or anything, but it still is a point. So all of the 2023 models have that same concept which, like you pointed out, you can curl up there with your thumb and really is a nice point there. You can also crack stuff open and like in a self defense situation, using the blade may not always be the best choice. For all those who are watching who know the steps of self defense there's starting just from a verbal point and then moving to lethal force, well, you don't just jump from point one all the way to the end. You work your way up. And sometimes just using an impact point can get the job done without serious damage and harming other people where it might not be needed. So I threw that in there just for that self defense part as well.

Bob DeMarco [00:14:51]:

The noggin knocker. I like it. Yeah. Sometimes you just kind of straighten someone out, I guess. Not that I've ever had to thank God, right? But I do like that. And then another thing that I like about your designs that well, there are a number of things, but I like how the scales sit. And the tang is slightly proud of the scales. And then the scales themselves are nicely contoured. They feel very comfortable and very hand filling. In this case. I haven't tried all your knives, but very hand filling, but not too big and fat, right?

Jack Billings [00:15:34]:

Yeah. I use the same thickness on all of the scales there. So they're all roughly a quarter inch thick on each side. So scales together are about a half inch thick, then thrown on the knife and they're all curved on the sides. They have a nice radius there because some knives I've seen, even some of my first knives I made, the corners or the edges were not rounded. And over time, using them in a hard use situation, you start to feel different points of the knife where if you're just holding it and doing normal things, opening a letter, whatever simple task may be, you won't notice it. So over time and overusing the knives, I was like, oh, we have to round the corners there to this specific type there because there's all different types of ways to round the corners. But through testing, I found this is the best way.

Bob DeMarco [00:16:36]:

So how do you make your knives? Take us through it.

Jack Billings [00:16:40]:

Sure. Yes. So for this line here, it's actually very different than the years before. And I can get into the years before in a second. But for this year's wine, the Blanks, I designed the actual design. So that's something I do myself every single year. Then I sent the design to a waterjet company. They cut out the design for me, mail me the blank, just the blank. And then from there, I put it on a jig where I get this nice hollow grind on all of the knives here. So get a nice hollow grind and put it on the jig there. Then I throw it in a stone washer. So puts a cool finish on there. It makes it look sort of gray, like a light gray, dark gray. Depends on how the light hits it, really. So put it in the stone washer there after doing the hollow grind. And then while it's in the stonewash, I start with G ten time. So the G ten, I cut out into the blanks. I get it in pretty big sheets, and then I just cut them out, drill them, do the counterbore on there, and then by that time, the G ten scale is finished, the knife is done being stonewashed. Piece the two together, do the Kidex, which is actually pretty simple. This is my first year with all the knives, having Kidex sheaths with them. And then after that, do my finishing touches and the knives are ready to go.

Bob DeMarco [00:18:22]:

Nice. What were they in before they were all in Kidex? What else did you offer?

Jack Billings [00:18:27]:

Yes, so before I offered leather sheets, that was something I had somebody else making the sheets. But I decided leather can tear. You can stab a knife through a leather sheath. A lot of bushcrafters really like leather, but through field testing and through people who actually use the knives. Said kitex sheath would be really great because you can adjust the clips on them where leather, you're confined to one setup. Also, you can clean them very easily. Just a little soap and water, and you clean a Kidex sheath. So Kidex has so many pros to it, I decide I have to switch to it. It's the best decision.

Bob DeMarco [00:19:14]:

Yeah. I love Kidex, especially on outdoor knives, but also on EDC knives. And this one is kind of well, it's sort of depending on your lifestyle, this could be EDC, kind of where I live, it's a little too much. But Kidex is nice because you can readjust it too. That's another thing. If it starts to loosen, you can just hit it with a gun and with a heat gun and get it nicely molded back in. This is a stock removal style of knife making. How do you do the heat treat?

Jack Billings [00:19:56]:

Yes. So the heat treat, how I get the steel, it is already to a very high rock. Well, it's in the high 50s there, so it's already at a spot where I was surprised when I tested it. I was like, oh, I guess I don't have to heat treat it, which is usually not the case whatsoever, so I don't have to heat treat it. Now, it's already at such a hard point where it really impressed me. When I first got the steel, it's 154 CM. So very popular steel. A lot of people know it very well, and it's just tough. It's stuff you can use. It's also a steel you can sharpen, which, if you're using some of the S ¥35 type steels, they can be hard to sharpen sometimes, especially for people who aren't used to sharpening knives. Where the 154 CM? It is a great steel for both use and for maintaining.

Bob DeMarco [00:20:58]:

So you're saying that wait, was this CPM 154 or.

Jack Billings [00:21:05]:

The first batch I did was CPM 154. Then, because of price differences and there were some issues I had to work out, I moved to 154 CM, so I did move to that. So it was just the first batch that had CPM, but still pretty similar steels. But the core of it, just great stuff to use in the field.

Bob DeMarco [00:21:33]:

Yeah, I love 154. Whether it's CPM or CM is one of my favorite steels. I have a lot of knives in this blade steel. It is tough. I can't say I've taken any of the other knives I have in 154 and batonned with it, which is what I was doing with this. And you're telling me you did not heat treat this?

Jack Billings [00:21:55]:

Correct, I did not heat treat it. And like I said, I was very impressed when I was working the knives in the field for the first time. That first run, like, no way. And that was actually a suggestion for my dad. I was like, oh, I got to change my heat treat process because it's a higher quality steel. He's like, Just test it first and see what you need to adjust. Well, after the testing, after the results, there's no need to.

Bob DeMarco [00:22:30]:

Yeah, it's really shocking to me. I'm a little flabbergasted, I got to say, because in my mind, if you don't heat treat it, you hit it. It's like hitting a stick of butter against wood. Obviously not. This has impressive qualities, and it's still paper cutting sharp. That's my lame test for just kind of feeling where there are snags and there's a slight glinting somewhere in here. Oh, it's up towards the front. That's right where it landed on a rock.

Jack Billings [00:23:05]:

Yes.

Bob DeMarco [00:23:06]:

Okay. All right, so then you got to tell me what kind of testing what were you doing out in the field where you determined you're like, this is good, just how it is?

Jack Billings [00:23:16]:

Yes. So when I test a knife, I go crazy with testing a knife. I start simple, cut some rope, just the simple stuff. But then I get into the chopping, taking a six to eight inch thick piece of wood and just chopping right through it like an axe. Something you would do with an axe. Just chop, chop, chop. Then for example, the point here, you've seen the Cold Steel videos where they stab it into a piece of wood and they start rocking it back. So that's what I did. Just over and over, trying to destroy the knife, trying to break it. And I didn't break any points off, didn't break any tips of the blade, nothing. And really impressed me. Even hammering the knife straight into a piece of wood and then hammering it left, right, just trying to bend it. Seriously, any way I can try to break my knife, I try. And with this year's line, I was not successful, which is a good thing.

Bob DeMarco [00:24:28]:

Yeah, no kidding. Well, okay. So you have a line of knives now. You have a nice size catalog, like, I don't know, ten knives or so.

Jack Billings [00:24:40]:

Ten models, something like there are seven knives. Yeah, very close. There are seven knives for this year. Every year, I release a new line of knives. I'm not sure if you know, but I am a big car enthusiast, and the whole line of knives idea came from the automotive industry. I thought if the automotive companies release a new line of cars each year, and they're all improved and they all have new features and a new look, I do the same exact thing with my knives each year. They look completely different than the year before. So I thought, name it. Like a vehicle, you have the year 2023. Easy to identify over time, the make, shed knives and then the model. So pretty easy to figure out, as we are all very, I guess, familiar with vehicle manufacturer names and how they put dates on their model. So I thought, let me do the same.

Bob DeMarco [00:25:44]:

I like that. Like you said, a familiar way of doing it. And I've noticed a lot of knife makers connect their passion for cars, especially with their passion for knives. Well, since we're actually on that topic, you sponsored a race team, is that right?

Jack Billings [00:26:05]:

Yes, I sponsored two teams. I have shed knives racing. I started that in 2020 as a way of getting shed knives into the industry, because I noticed through dirt track racing, which is what I sponsored, a lot of the people who watch dirt track races, they're also outdoor enthusiasts. They love to camp, they love to hunt, they like to fish. And what type of knives do I sell? That same category. So what better way to get my brand in front of my clientele than racing? And it's also fun to watch.

Bob DeMarco [00:26:43]:

Yeah, it is. It's fun to do, too, on the streets around where I live. Apparently, they love doing that, the racing and the knife thing, I should say cars and knives, very definitely you see a parallel between them. But your knives, you're not doing a complete redesign. Very much like the car industry, there is a memory of the knife before as it moves forward. How do you evolve your designs? One year to the next. Do you sit down at a pad of paper or does it come from working metal? What do you do?

Jack Billings [00:27:25]:

So I sit down with a normal sheet of paper, nothing crazy, and just I look at the knives I have made, I lay them all out. I keep one of each model year after year, and I set them all down. And for example, I brought a 2022 sheep's foot. You can see is very different from the 2023 sheep's foot, but it's also similar in some aspects as well. So I lay them all down and I start writing or drawing the general shape. As you can see here, the sheep's foot, the 2022, has a pretty similar shape to the 2023. But then I start improving small things like the back of it. You can see it's just an oval. Pretty much got the half inch linear toll. Let me add some different components here. Let me change the shape of it, let me change the geometry. So I start adding small things that over time, over dozens and dozens of designs. Specifically with this one, I probably did 35 or 40 designs before I landed this one. It's just drawing over and over and over until I find one that locks. I'm like, this is it. And then I put it into production, which is just doing it all by hand to see how it works, how it looks, and then through that as well. I'm all about constant improvement, and every year I have constantly improving designs. But even my process, as I make the knife, as I make the new knife, I see, oh, I can take a minute off of this process while maintaining quality. Oh, I can improve quality with this additional step. Look at that. So there's all sorts of things I look at, both in the knife itself and the time behind the knife. I look at all those things on how to improve. So to finish up the answer here, yes, I design the knife, but I also design the process as well. I write the process down and see, oh, I can do this a little different. Oh, I can add this, I can subtract that. Just constant improvement is what I'm going for.

Bob DeMarco [00:30:08]:

So when you made the change from wrapped handles to handle scales, was that a business decision or was that an ergonomics quality of feel kind of decision?

Jack Billings [00:30:22]:

So it was a ton of things, really. At Blade show in Atlanta. I set up last year. So 2022 I set up, and a lot of people liked the 550 cord. They were really into it. But they said, for next year, how about G Ten? We love g ten. It's a great material. Try working that. And then I started messing with it a little bit and I was like, actually, this is a great addition here. There's nothing wrong with a 550 cord handle here. There's nothing wrong with it. You can take the 550 cord off and use it for so many things, but the G Ten is great because you get better grip. And I also made it so you have interchangeable parts. The screws in the handle itself are the same screws in the sheath here that put the clip on. So if you lose a screw in the clip, which sometimes that happens, you're out in the fields, you knock it against something, you break a screw, you just pull the center one out and boom. You have an interchangeable part, which I have not seen with any other knife company. And if someone can show me a company who's done it, I'd love to see it. But until then, this is a first.

Bob DeMarco [00:31:43]:

Well, I love that, and most knife nerds do love some form of universal hardware, but that usually comes into play mostly with folders. Yeah, it's cool to hear that that's a part of your planning in the designs. When you started way back when you had partners and you ended up carrying the torch, do you work alone now, or do you have others that you work with?

Jack Billings [00:32:16]:

Yes, you're right. I did start with a team. I started with two friends, and then that team grew to eight people. I had eight other people working for me. And then at that time, it was really around the Pandemic, around 2021. It was actually a good point. I was thinking, I was like, you know, I can do a lot of this myself. I want to really dive into the process itself and learn it and find how to improve it. And the eight other people I had on the team, we were all 1516 years old, and so interest changed very fast, so they wanted to move on to bigger and better things. So it worked out really good for all of us. But today I do everything myself. All the marketing, all the content, all the production, I do it all myself. There are a few things I outsource, like cutting out the water or water, jetting the blanks, stuff like that. I outsource. But that's not much in the big picture there.

Bob DeMarco [00:33:27]:

So would you say that you are entrepreneurial in spirit or a craftsman in spirit, and not that those are mutually exclusive, but I'm curious because you do seem to have a pretty nimble business sense.

Jack Billings [00:33:45]:

Yes, I have been running businesses for quite a long time. Businesses, meaning maybe a lemonade stand, selling lemonade, selling stuff at school that I made, just stuff like that. I've always had that mindset for business and for creating stuff and for contributing positive things to the world through business. So, yes, I am a craftsman, but I have a very strong mindset for the entrepreneur. So the two come in hand, so they work very well together. But that business mindset has definitely been with me for quite a long time.

Bob DeMarco [00:34:34]:

That's like having a law degree. With a business sense, you can do anything. And actually, I've spoken to a lot of people on this show who have been pretty business savvy, so I don't have many examples to point to. But I could see how one could get lost in the pleasure and the struggle and the frustration of the creative side of things, making the knives. But figuring out how to grow your business, that's another aspect altogether, right?

Jack Billings [00:35:07]:

Yeah, there's all sorts of stuff to look at when I am both passionate for business, but also I have an interest in the product itself. But through all of it, it really comes down to one thing constant improvement. When I was in the shed during the summertime, that was really when my mind was working, really thinking, man, how can I improve what I'm doing now so I can be in a better shop, so I can be out of the 100 degree temperature making knives? So it's stuff like that. I think all business owners need, all people need. They need those tough times, being in the spot you don't necessarily want to be in. But for all of it, I learned something. I enjoyed it at the time. I made the most of it. Of course, we had a lot of great times in that shed. You know, the team, we had a lot of great days in that shop. But the mind is always looking for the best thing, the next improvement. The two come together very well.

Bob DeMarco [00:36:20]:

Oh yeah. So in terms of automating to make yourself more as you strive for this improvement, especially when you're talking about process, some of that might mean automating. How have you considered that possibility?

Jack Billings [00:36:38]:

Yes. So since I am a one man show, the more efficient the better, while maintaining quality. So I've looked at a few things, like a water jet, cutting the blanks instead of cutting them out with an angle grinder, which I had done every year before. So that helps. Right now I do all the G ten scales by hand. So a CNC machine is my next addition. So I can cut everything out with a machine. And it's pretty much like another employee. It's working while I'm doing something else. Then we'll get on to the online part of it, the social media, the content. I schedule a lot of that stuff, so whenever I have an idea, I just come up with it, put it in the schedule, and that way stuff is always coming out. That's another platform working for me all the time. There's all sorts of stuff I look at to make the process faster, but also improve quality if not maintain it at the same time.

Bob DeMarco [00:37:47]:

Yeah, that was something you mentioned in your letter to me in the box here was that you were looking to automate the production of your handle scales using CNC. And I've spoken to a number of fixed blade makers who do that and I think that it's a brilliant solution to what I have a feeling is an arduous part of the process, especially with Ergonomics. You don't want to mess around too much with that. You don't want to rush it when you're doing it by hand. And you want to make sure that it's right and that every knife that everyone picks up feels basically the same, right?

Jack Billings [00:38:31]:

Yeah. And that's a part of handmade knives. I'll actually show you one here. This was from 2018. Here, I brought this. So this was the first line of knives by shed knives. So if you have seen, which I know, you have seen the 2023 box and what comes with it. But for all of you who are watching, the new line looks much better than this. But this is what I was doing at the time, so you can see the improvement over the time. This is what I was first doing. Cutting it out by hand, doing the 550 cord, working on a small one by 30 harbor freight belt sander. Just something I could get my hands on compared to that 2023 US Tonto you have, which I actually have one right here. Over time, I look for ways to constantly improve, like I said, and ways to make the knife better. And yes, making it by hand is great. This is a handmade knife, but finding other resources to use that just enhance the knife. Yes, this is still handmade, but I found other ways to enhance it. So that's something I've also thought about. The more I move into machines like CNC scales, waterjet blanks, stuff like that, the farther away I go from handmade knives. But really, the core focus of a knife is cutting it's, using it, and that's where it comes down to it's okay to have a machine make some of the process because it will later on enhance the person's time who's actually using it. They'll have a better experience because I've used better processes throughout the years.

Bob DeMarco [00:40:39]:

Yeah, no doubt. You can tell that a knife has been zero, like the design efficiency has been zeroed in on when you're using it. And that only comes from that sort of constant looking over and over and over. That's something I ask some people is, do you want to have a knife company that produces a whole bunch of different models, or do you want to be a knife company that has a couple of models that you keep redoing and redoing? Like the difference between a Tops knives and Chris Reeve knives, where everything is. But in your case, it kind of sounds like you're bringing those two models together.

Jack Billings [00:41:27]:

Yes, that's right. I talked about how many models are in the selection. I have, of course, looked at the Tops knives selection. I know the Tops teams are a great group of guys, and they do have quite a lot of models in the selection. They've got high 300, low 400s, they have a ton of models where, at least for me, for my goals in business, I find, let me stick to the best, let me narrow it down and improve on those. But as time goes on, I will make more and more knives and more and more models. But I think for long term planning and for what I'd like to achieve in business here in this industry, is stick with the best knives for the task. I don't need to go out having thousands and thousands of models. Just have the best. You don't need a ton of models when you have the best.

Bob DeMarco [00:42:32]:

Well, okay, maybe that answers the question, but how would you lay that out? What do you want to achieve in this industry?

Jack Billings [00:42:39]:

Yes, so really the end goal is if you are a knife enthusiast, you carry a Shed Knives knife. That's really the end goal. Like the buck 110. Everyone's got a buck 110 or at least, you know, someone who has a buck 110. So that's a classic in the knife industry, as we know. And my long term goal is Shed Knives becomes that classic. Everyone has one of my knives in their collection. So really, that's it.

Bob DeMarco [00:43:16]:

So here's a question. How are you prepared to or what do you think of customer feedback? You'll have people, no doubt, who say, oh, that grind is too low, I need something slicy. Or who say, we want you to use a different steel because we're really into this steel. And then that forces you into a different sort of protocol because you're going to have to heat, treat and do different things because you struck gold getting a steel that doesn't require that. How are you prepared to evolve for that kind of eventuality?

Jack Billings [00:43:57]:

Yes. So, as you know, customers desires and what we knife enthusiasts like is always changing. And businesses need to change as fast, if not faster, than the customers change in interest. So when people come to me and say, hey, I like how the grind is great, well, now I know I had a dozen people say that, let me keep it. Or if I have people say, you know, Jack the Kidex sheaths are cool, but we actually like leather, then boom, I just move right back to leather and I have all sorts of backups ready to go. I have designs, I call it the Shed Knives vault. There's all sorts of designs, all sorts of stuff in the vault that's just ready to roll out. So when customer interest changes for the masses, because each person has their own niche preferences, but for the masses, I'm ready to roll out with whatever they want to change, because at the end of the day, it's the customer who uses it, it's the customer who buys. So I got to make what they want?

Bob DeMarco [00:45:13]:

Yes. Give the people what they want. Absolutely. That's what people want to hear, especially knife makers. Not knife makers, knife hoarders, I mean, buyers like myself. No, I mean, because being totally honest, to use this to its maximum potential, which I haven't yet, but just in taking it out and thumping, it totally extracurricular behavior for me. That is not part of my lifestyle other than I think it's fun to do. But for someone who really does rely on a tough knife like this, they're going to want to know that you're listening.

Jack Billings [00:45:56]:

That's right.

Bob DeMarco [00:45:57]:

So what are your ways of listening and receiving feedback?

Jack Billings [00:46:04]:

Yes. So if you've bought a knife, for those of you watching, if you bought a knife from Shed Knives in the past few months, I always send an email out right after you order a knife online. And I ask, well, how'd you hear about us? Because that helps. See what I'm doing good, what's working. And then later on, there's all sorts of opportunities I put out there for customers to give their feedback. I do surveys. You get a discount code, you get 15, 20% off down the road. I do posts on social media asking, oh, what do you like about that? The Atlas will say, what do you like about obscure, what's your favorite knife? Stuff like that. And then I'm also taking a look at what other companies are doing, what other people are saying. I'm connected to quite a few different companies, so I guess you could say an inside knowledge there on what's going on behind the scenes, what feedback other companies are hearing. So that way I'm a big fan of let me see what is going on in other places first before just running in and rushing to it. I don't rush to failure, so I see what's happening, analyze and adjust from there. So there's all sorts of opportunities for people to give their feedback and, hey, I like the knife. Hey, we could adjust this then, great, let's do it.

Bob DeMarco [00:47:41]:

So you indicated you have a lot of friends at knife companies. That's great to have. No doubt, because knife makers are some of the coolest people I've met. But in terms of the rest of the community, the knife buying community, and the peanut gallery online, what has the feedback been from or what are your feelings and take? On the knife community?

Jack Billings [00:48:09]:

Yeah, on the knife community. Well, like I mentioned, interests are always changing. Oh, my goodness. I noticed the community that a lot of people are going after the benchmade bug out type of knife, a lot of people are going for that style. That seems to be something that's trending now, at least for what I see. But yeah. Oh my goodness, I didn't even know where to start. There's all sorts of stuff going on. But I guess to answer that a little bit more, how I find that stuff online forums, knife forums, knife pages, even some of the Shed Knives platforms. Really, all the platforms, they've turned into really nice communities where people can connect with like minded individuals. Like, for example, the shed knives. TikTok People are always talking to each other. Oh, did you see this knife came out? Did you see that model? It might not even be from Shed Knives. It might be from somewhere else, but I'm still seeing okay, great. This is trendy. Oh, they want to see this improvement. So there's all sorts of stuff going on. I definitely miss most of the info, but if I can catch on to some of the key points, then great.

Bob DeMarco [00:49:31]:

Have you felt support from the general knife public? You know what I mean? Yeah, I feel like it's a supportive crowd out there.

Jack Billings [00:49:41]:

Oh, for sure. Yes, definitely supportive. I was actually at a show a couple of weeks ago, and I guess now about a month ago, and a guy came up to the table. He's like, hey, Jack, I remember when you were outside selling knives in the parking lot and when it was your first show back in 2019, and he was very supportive and just stuff like that. It's like, man, people, they're so supportive. Even at the very start. Maybe the knives weren't the best, but the idea, they like the idea. So there's all sorts of support, and I'm so thankful for that. I mean, seriously, there's been so many people over the years and even now that are here to support both me and all sorts of knife makers out there. So there really is a great support in the community.

Bob DeMarco [00:50:40]:

You're going to be at Blade Show this year, right?

Jack Billings [00:50:43]:

That's right, yes.

Bob DeMarco [00:50:44]:

Awesome. I look forward to meeting you in person. I love Blade show. This will only be my third year going, but, man, I love that show.

Jack Billings [00:50:56]:

Yes, it is awesome. It's my third year as well. Second year as a vendor. And yes, it's an awesome place, and that's really where I get a lot of customer feedback and what people like, what trends are in. So Blade Show, it is the place to be.

Bob DeMarco [00:51:14]:

Yeah. So make sure everyone you'll be at a table over on that big area of tables on the right.

Jack Billings [00:51:23]:

No, I'll be 20, 416. I'll be in the smaller room. I've got a corner and then an inline there. So nice big set up. There is seating as well, so you can have a place to sit. So at the shed knives booth. That's right.

Bob DeMarco [00:51:38]:

I love that room. That's where I spend most of my money.

Jack Billings [00:51:43]:

We're right there.

Bob DeMarco [00:51:44]:

We'll be right there. Hey, so you're a young man. Anyone with eyes can see that, and we know that you've been doing this for a shortish period of time, but you've definitely formed a brand identity. You've formed a really nice catalog of knives. I've had a chance to experience your work and put it through its paces. Your product is good, and you're looking at things from an earlier stance in your life. What kind of advice would you give your peers? People who are just about your age, they don't have to be your age, but someone who's young and coming out and thinks they might want to start a business, a business in knives or a business at all, what kind of advice would you give them?

Jack Billings [00:52:40]:

Sure. Well, I would give a few things. First off, find something you want to achieve. Find a goal. Find a long term goal. Pick an industry, and usually that's where the goals come from. Pick an industry. If it's the knife industry, pick a goal in the knife industry and then just stick with it. And that's what I've done. Just stick to that goal. And that's why I recommend you can't go wrong with that. Just no matter what, limit the distractions, just constant improvement. Just find a way to achieve the goal. If you work hard enough, I guarantee it can be done, because I've done it before. The small goals, the small wins, lead to the big wins. So, really, that's what I would recommend. But I guess some more personal advice, enjoy the process as well. Don't be so focused on that end goal. A quote I use all the time is the man who enjoys walking walks farther than the man who enjoys the destination. So enjoy the process, enjoy what you do, and no matter what, just stick with it. Pick the right thing and stick with it.

Bob DeMarco [00:54:05]:

Yeah, Jack, but I don't have a two x 72 grinder. I can't make knives.

Jack Billings [00:54:09]:

Well, there's all sorts of options. I started with a palm sander, and then it came from there. I got an angle grinder, so then I could cut my own blanks out. Get creative. You don't necessarily need to sell stuff. You can trade it. That's what I did. I wasn't at the point to sell knives, so I would trade them. I'd get better machines. Just get creative. There's all sorts of ideas out there. There's always a solution. You have to have a revolving door of solutions. That's what I say all the time. You got to have a revolving door of solutions, because life is a revolving door of problems.

Bob DeMarco [00:54:51]:

You got that right. And on that note, Jack, thank you so much for coming on the Knife Junkie podcast. I really appreciate it. It was nice meeting you and talking about your knives and getting your business sense there.

Jack Billings [00:55:04]:

Awesome. Well, it was great to be on the show. Thank you very much.

Bob DeMarco [00:55:07]:

My pleasure. We'll talk to you soon.

Jack Billings [00:55:10]:

All right.

Announcer [00:55:11]:

Don't take Dull for an answer. It's the Knife Junkie's favorite sign off phrase. And now you can get that tagline on a variety of merchandise, like a T shirt, sweatshirt, hoodie, long sleeve tea and more. Even on coasters tote bags, a coffee mug, water bottle and stickers. Let everyone know that you're a knife junkie and that you don't take dull for an answer. Get yours@thekjunkie.com dull and shop for all of your knifejunkies merchandise@themifejunkie.com. Shop.

Bob DeMarco [00:55:43]:

There he goes. Ladies and gentlemen, Jack Billings of Shed Knives. We know he has a bright future in knives. I also think he has a bright future in motivational speaking. I liked that last bit about the revolving door of solutions because, yes, there are a revolving door of problems. Join us next week for another great conversation. And don't forget about Wednesday for the midweek supplemental and then Thursday Thursday night Knives right here, 10:00 p.m.. Eastern Standard Time, live on YouTube, Facebook and Twitch. For Jim working his magic behind the switcher, I'm Bob DeMarco saying until next time, don't take dull for an answer.

Announcer [00:56:21]:

Thanks for listening to the Knife Junkie podcast. If you enjoyed the show, please rate and review@reviewthepodcast.com for show notes for today's episode, additional resources, and to listen to past episodes, visit our website. Thenifejunkie.com you can also watch our latest videos on Youtube@thenjunkie.com. YouTube. Check out some great knifephotos on thenightjunkie.com Instagram and join our Facebook group@theknifejunkie.com, facebook. And if you have a question or comment, email them to bob@thenifejunkie.com or call our 24/7 listener line at 724-46-6487. And you may hear your comment or question answered on an upcoming episode of the Knifejunkie podcast.

Share This With a Friend >>>

For early access to The Knife Junkie podcasts and YouTube videos, receive Knife Junkie stickers and be entered into the monthly knife drawing giveaway, join The Knife Junkie’s Patreon group of awesome supporters.

Let us know what you thought about this episode. Please leave a rating and/or a review in whatever podcast player app you’re listening on. Your feedback is much appreciated.

Please call the listener line at 724-466-4487 or email bob@theknifejunkie.com with any comments, feedback or suggestions on the show, and let us know who you’d like to hear interviewed on an upcoming edition of The Knife Junkie Podcast.

To listen to past episodes of the podcast, visit theknifejunkie.com/listen.

StreamYard simplifies the process of live streaming and recording videos. It allows you to create content seamlessly from your browser. With its versatile features, you can multistream to various social media platforms, host regular shows with guests, conduct webinars, record podcasts using local recordings, and create videos with ease. StreamYard has become a popular tool among live streamers, video creators, YouTubers, and podcasters. Its impressive array of features includes live streaming, webinars, local recordings, screen sharing, and more, ensuring that you can produce professional and polished content every time. Get $10 in credit on StreamYard with this link! (new customers only)

Shopping for a Knife?

Support The Knife Junkie Podcast and YouTube Channel by Buying Through My Affiliate Links

Bamba Forge

Bamba Forge

eBay

Field Supply

James Brand

Knives Ship Free

Off-Grid Knives

Vosteed Knives

WE (Civivi) Knives

Other Products and Services

Podcast Hosting

Website Hosting

Groove (Free Account) – Replace 17 Apps/Services in Your Business

Knife Books

Rakuten (Cash Back for Shopping Purchases)

Upside App (Cash Back for Gas Purchases)

TubeBuddy (Free Browser Extension and Mobile App for YouTube Creators)

Follow The Knife Junkie

Visit The Knife Junkie website

The Knife Junkie Listener Line — 724-466-4467

Email The Knife Junkie

Follow The Knife Junkie on YouTube

Follow The Knife Junkie on Instagram

Follow The Knife Junkie on Twitter

Join The Knife Junkie Facebook Group

Affiliate Disclosure

In the name of full transparency, please be aware that this website contains affiliate links and any purchases made through such links will result in a small commission for me (at no extra cost for you). If you use these links, I might be rewarded credit or a small commission of the sale. If you don’t want to use these links, no problem. But know that I truly do appreciate your support.