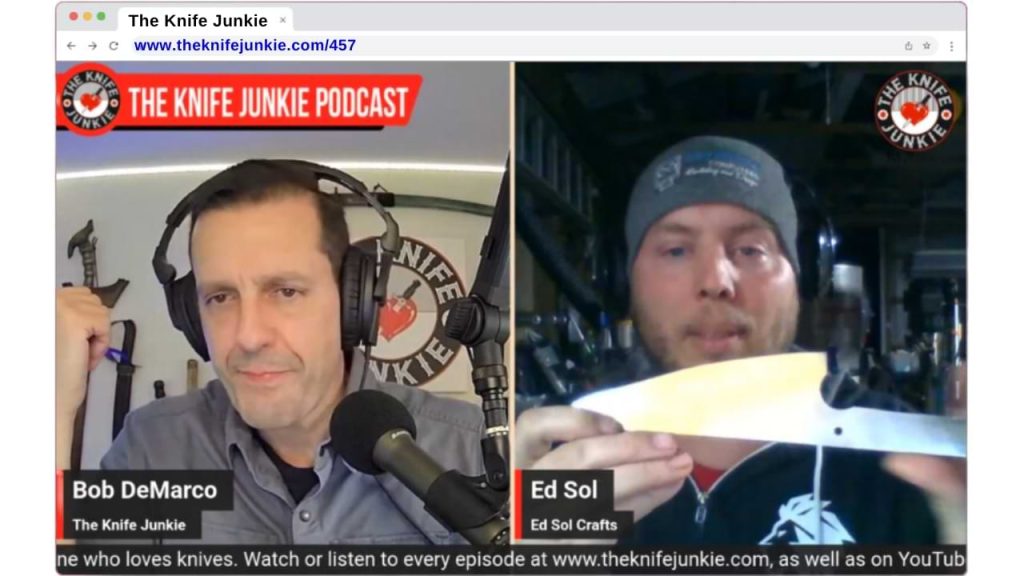

Ed Sol Crafts – The Knife Junkie Podcast (Episode 457)

Ed Sol of Ed Sol Crafts joins Bob “The Knife Junkie” DeMarco on Episode 457 of The Knife Junkie Podcast.

Ed was born and raised in Mexico and now lives as a bladesmith and blacksmith in Indiana. The stark contrast between urban and natural environments inspires him creatively.

Ed was born and raised in Mexico and now lives as a bladesmith and blacksmith in Indiana. The stark contrast between urban and natural environments inspires him creatively.

As he grew up, Ed loved to work with his hands, drawing and building things, which eventually led to cooking. His love of knives grew as he learned more about cooking and kitchen cutlery. Knives designed for particular tasks and materials that excelled at those jobs became his main concern in knife making.

Ed won first place in the edged category for the 2021 Indiana Blacksmithing Association and is currently working towards his ABS Journeyman accreditation. Ed was also a finalist on Forged in Fire, Season 9, Episode 8.

Most recently, he has collaborated with TM Hunt Custom Knives to create the Brain Shovel, a push dagger built on a knuck platform.

Find Ed Sol Crafts online at www.edsolcrafts.com, Instagram at www.instagram.com/ed.sol.crafts and on Facebook at www.facebook.com/Ed.Sol.Crafts.

Be sure to support The Knife Junkie and get in on the perks of being a Patron — including early access to the podcast and exclusive bonus content. You also can support the Knife Junkie channel with your next knife purchase. Find our affiliate links at theknifejunkie.com/knives.

Ed Sol of Ed Sol Crafts is featured on Episode 457 of #theknifejunkie #podcast. Ed was born and raised in Mexico and now lives as a bladesmith and blacksmith in Indiana. He was also a finalist on Forged in Fire, Season 9, Episode 8. Share on XThe Knife Junkie Podcast is the place for knife newbies and knife junkies to learn about knives and knife collecting. Twice per week Bob DeMarco talks knives. Call the Listener Line at 724-466-4487; Visit https://theknifejunkie.com.

©2023, Bob DeMarco

The Knife Junkie Podcast

https://theknifejunkie.com

Transcribe Your Podcasts and Videos: https://theknifejunkie.com/magic (affiliate link)

Announcer [00:00:03]:

Welcome to the Knife Junkie podcast, your weekly dose of knife news and information about knives and knife collecting. Here's your host, Bob the knife junkie DeMarco.

Bob DeMarco [00:00:16]:

Welcome to the Knife Junkie podcast. I'm Bob DeMarco. On this edition of the show, I'm speaking with bladesmith and blacksmith Ed Sowell. Ed was introduced to me by a friend of the show Who knew that a recent collaboration knife of his would speak my love language. He was right. But when I looked further and I saw a man with a passion and talent from metal. With a forged in fire pedigree, I had to know more. So here, we're gonna talk about it.

Bob DeMarco [00:00:43]:

But first, Be sure to like, comment, subscribe, hit the notification bell, and download the show to your favorite podcast app. And as always, if you wanna help support the show and check out All sorts of interview extras like the extra conversation we have with Ed Saul after this main interview. Please go to the knifejunkie.com/patreon and check us out there. Again, that's the knife junkie.com/patreon.

Announcer [00:01:07]:

If you search Google for the best knife podcast, The answer is the knife junkie podcast.

Bob DeMarco [00:01:15]:

Ed, welcome to the show.

Ed Sol [00:01:17]:

Hey. Thanks for having me. It's a pleasure to be here.

Bob DeMarco [00:01:19]:

Oh, man. It's a it's a pleasure to have you with us. So you did me a solid and sent this out for me to check out. This is a recent collaboration. You gotta tell me about this because I've never seen A knife quite like this, and I've shown this off a bit on the podcast and on Thursday night knives, so people are probably familiar with the brain shovel. Tell me about this.

Ed Sol [00:01:45]:

Basically, I'm apprenticing with Todd Hunt, fantastic Knife maker, awesome human being. I can't say enough things about him, but we, every once in a while, we'll do a collaboration where we both work on a project, and, he said, hey. We should do a dagger. I I think we should do something fun, And I'm like, if we're gonna do a dagger, why don't we do a push dagger? And we were talking about it. We never liked that t shape that most daggers have for a handle. My feel is very limiting, and it basically, you have to have a specific type of hand for it to be comfortable in, And we just thought we could honestly, we thought we could do it better. Todd makes this thing called the ring pop, which is basically a knuckle duster with spikes, And I asked, hey, if you take your handle and we just basically put a dagger on it, like, would you be offended? Because I love your I love your NOC. You can hold it, you know, 30 different ways.

Ed Sol [00:02:43]:

It's amazing. He's like, yeah, let's do that. And as we were prototyping it, I heard through the grapevine about a steel, this amazing steel called Apex Ultra, and I was like, This would be perfect. Like, it's the hardest The the highest toughness at the highest hardness, which is 67 Rockwell, and it's, like, off the chart tough And super fine grain structure, like, it's just meant for straight razors and b use, like, it was a perfect dagger, steel. And I got some and basically, you know, tracked it down. I got some, and we just made the best punch dagger we could think of. It's a short version, and it's super comfortable, and like I said, it's just awesome.

Bob DeMarco [00:03:29]:

So how did you work with the, Apex Ultra? I know you, from Forged in Fire, but did is this a steel that you forged or how did how did you guys work with this incredibly hard steel?

Ed Sol [00:03:40]:

So it's meant to be forged. Unfortunately, I like it to be used. So I've, I got it in the bar stocks and we could just, you know, cut it out and shape it to what we need it to. So, the first thing we did was we took the bar, we made a bunch, drew the, you know, traced our blank on it, And then we took it to a metalworker, which is basically an industrial machine for punching holes in this thick steel, and, we broke it.

Bob DeMarco [00:04:08]:

Oh my god.

Ed Sol [00:04:09]:

Yeah. It's ridiculous. Even in its softest state, Apex Ultra is super tough. So we basically we killed the metal worker and we Snapped the bar a few times, so then we just went old school, just drilled and drilled the holes, did everything by hand, and, because which realistically, we should have forged it and punched and drifted the holes. Mhmm. But we just tried doing it, like I said, Manufacturing it to make them all identical because when you forge it, things are never the same. Like, you can get close, and one of the things I'm learning from Todd is repeatability, And you want everything to be as identical as possible because, you know, 2 people have the same knife, you want it to be the exact same knife. Not like, oh, look, mine's a little bit bigger than yours, So, yeah, so we basically just did it all stock removals And suffered for it.

Ed Sol [00:05:05]:

So we're we're talking about the next batch and how we're gonna use the forge to do it hot to make our lives that much easier.

Bob DeMarco [00:05:13]:

Okay. Let me ask you a question. Yeah. Is there a, is there something that you wanna get out of Apex Ultra In this knife in particular or is it just, a value added? You know, look at this exotic steel you're getting when you buy this.

Ed Sol [00:05:30]:

It's really, it's about the best product possible. It we joked around the shop that if you got into a knife fight, somebody has a Walmart knife, You could literally punch and break the knife with a brain shovel. It's that much tougher than anything else out there.

Bob DeMarco [00:05:45]:

Okay. So before we get to what is a knock, because Some people might just be listening and might not, see what I have in my hand. It's a, it's a dagger, a short stout dagger of about Two and a half inches. And then at the base of it, there's a large circle, and on either side, is a buttress that attaches to a handle. So it's kind of like a knuckle duster, a single knuckle knuckle duster, but tell me about Nux and and how how you sort of thought that this would be the right platform for a dagger.

Ed Sol [00:06:18]:

I've helped, like I said, Todd makes the ring pop, which is Yep. The the knuckle duster or his version of it, and I've held a lot of them as I help, you know, help them finish it, putting the handles on and finishing the handles. And every time I held it, I just really liked the way it feels in your hand. And then we were playing around with, like I said, put push daggers, and, like, every shape we drew out and traced out just Didn't feel as good. And then I've got famously small hands. So anything he held and he liked, I didn't. Anything I liked, he said felt like a little girl's toy. So finally, I'm like, you know what? Let's just go with the Ringpop.

Ed Sol [00:07:01]:

We both love it, And that's better than, you know, the 15 drawings we have that we're both criticizing each other about, and he's like, you know what, that's a great idea, So we did it.

Bob DeMarco [00:07:12]:

Yeah. I I think you're right. I have slender fingers, and This still feels comfortable if you take that traditional, center line grip, for this push dagger. But, actually, I find it most comfortable Like this right on the forefinger. And and with that lanyard you put in there or on there, it it it's a it's a great grip. And then it's got this beautiful, beautiful leather sheath, that drops in your pocket, and then it only leaves just a little bit, hanging out of your pocket.

Ed Sol [00:07:46]:

Yep. And that's another thing is, you know, you're carrying something that's basically meant for self defense, and you don't We try to find a way that you could comfortably carry it and not advertise that you're basically carrying a dagger or, you know, A self defense weapon. So you can, like I said, you tuck it in your pocket or you could put it on the inside of your jeans, so just little clips hanging out. Mhmm. Very comfortable, everywhere I've tried to wear it, and like I said, it just looks like a little accent piece around your waist. Nobody says anything. Nobody's threatened. At the same time, if you need it, it's there.

Bob DeMarco [00:08:20]:

Yeah. And and all of, well, this handle is I forgot to ask you. Is this cocobolo, or what kind of wood is it?

Ed Sol [00:08:26]:

It is actually a Dyed curly maple.

Bob DeMarco [00:08:29]:

It's beautiful. And, all the other handles, on the website are beautiful as well. So that's that's a benefit. You've got a a real weapon type thing here, but it's beautiful and confusing. You know? Someone will look at, Oh, you know, that's interesting. I've never seen anything like that. I'm sort of menaced, but it's so beautiful that

Ed Sol [00:08:49]:

yeah. You know what I mean?

Bob DeMarco [00:08:51]:

So that that's definitely something that struck me, when you sent this to me. You also sent, oh, it's just out of reach. You also sent me another, knife of your making, a straight blade, hunting knife. Yep. A a beautiful thing. So tell me, let's let's get into how You got into knife making and how you got into metal. Take us all the way back.

Ed Sol [00:09:15]:

So I've, So basically, I started off wanting to be a woodworker and just for whatever reason, I was just in a place in my life where I got set up with video games. Apparently, I matured a little bit, so I was just going down the YouTube rabbit hole and I was just watching people whittle and make, You know, carving with spoons and all sorts of basic, you know, hand you know, things that were hand carved. And my wonderful wife, Same thing. Being the same she is. Says, hey, Ed. You know, there's, down in Franklin, Indiana, there's this awesome Woodland Convention. Do you wanna go? And I'm like, That sounds amazing. So we packed up the kids and drove down there, and it was all oohs and ahs.

Ed Sol [00:10:00]:

And while I was there, this Guy just, I guess, saw the look of a deer in the headlights. He's like, come on over. Like, have you done any work with you? I'm like, god. He's like, well, what do you wanna And I'm like, I wanna make spoons and spatulas. He's like, dude, you need these 2 tools and this book, $100, you're ready to go. I was like, $800, I'm in. So he's like, oh, by the way, I made I made the 2 little wood, you know, the wood carving tools, that's why the handles are a little iffy, But here you go, they're gonna be great, and I was like, Still, $100, I'm in. And they were absolutely fantastic, and as I Wanted to go more into woodworking.

Ed Sol [00:10:35]:

I just went to Home Depot, and I was like, oh, a chisel's a chisel, you know, knife's a knife, Bottom, and they were hot garbage. Like, I could not sharpen them. Every time I was using, I was spending more time sharpening the needle. Now I was like, I was gonna go online, buy the best wood chisels that are out there and just, you know, call it a day. Right? And I go on and it's like a Lee Valley Sweetheart or something, you like each chisel's $350 and you can set a 5 to get them. I was like, there's no way. For the price of 2 chisels, I can buy All the tools I need and I can make my own, and I did. I I bought an anvil, I I bought a forge, And then I just as I was learning how to, you know, move metal, I just fell in love with knives.

Ed Sol [00:11:21]:

So that's basically how I got into it. It's my wife's fault.

Bob DeMarco [00:11:26]:

That's amazing. It's not, it's not your average, lady or wife who will say, hey. There's a whittling convention, you know, in the next state, let's go. That's that is that is really cool. I mean, well, hats off to her indeed. So it's interesting that, you were brought to metal through wood, you know, to to Two components that go into lots of different knife making, but but, you know, kind of a Well, 2 very different, materials to work with, let's say. But but it was the steel, and And I also know that you do some cooking or did some cooking. Right? Yes.

Bob DeMarco [00:12:10]:

So that did that deepen your attachment?

Ed Sol [00:12:14]:

Yes. That, it's one of those things everybody says work with what you know and you love, and I'm Hispanic, believe it or not. That had a thing for blond blood women, thanks to good looks, but I spent my whole life in the kitchen with my gran with one of my grandmothers Basically all day every day, you know, helping to make food either for that day or also on my father's side. Every Saturday was a big family lunch, And my poor grandmother couldn't do it, so I'd go over there Friday. And Friday after school, we'd start cooking for, you know, Sunday lunch, and then As she got older, she would, she wanted to take more cooking classes, but she can't drive at night because She's old in this dark, so I would take her and then I would you know, obviously, if I'm taking her, you know, we both signed up for cooking classes And that's one way we bonded, so I love to cook and that just informed me on, like, my knives. I focus to make a single purpose tool the best that I can, and I like slicesty things. So all my knives Our very slice of vegan kitchen knives, the utility knives, they're all I'd say they're just fantastic slicers because that's what I know.

Bob DeMarco [00:13:28]:

So how did you make the leap? First of all, I think that's a beautiful story. I I was close with both of my grandmothers, and the idea of taking a cooking class, with with your grandmothers, I love that. But how did it how did it Come to pass that you're like, you're cooking, you're cooking, and suddenly or not suddenly, but you decide none of these knives are doing it for me. I need to make my own.

Ed Sol [00:13:53]:

Well, that's the thing is, again, I grew up not knowing what I don't know, so every knife that you buy, you buy it from Walmart or wherever for $20, And then as you go through, well, this is kinda garbage, or I like this, I'll look at other knives, like, similar to that but not exactly the same, And, I mean, we were like, I kid you not, we were going through a nice, you know, Walmart nice every 90 days between the 2 of us. Like, we just we would and again, you know, we didn't know what we didn't know, and we'd be very aggressive with our sharpening. Yeah. And, you know, you're processing meat because, again, you're feeding a Mexican Family of 30, like, you're gonna sharpen that bad boy a lot. Yeah. And just you would just flash your knives like, well, this one's garbage. Now, Juanita, what did you like? I'm I'm going to Walmart to buy whatever. I'm a buy us a couple extra knives.

Ed Sol [00:14:40]:

I said, well, I like the German, you know, the German style chef. Try this, try that, Avoid that. And, long story short, like my chef knives, like, I've got one that I'm working on right here, like this was in a cooking class that we took. I I wish I remember who made it, but, it was this similar to shape, and we both loved it. My grandmother tried to buy it off the guy that was giving us the cooking class and he said no. And, it just sat in the back of my head for 20 plus years. And then when I started making knives again, I defaulted to French chefs, German chefs, and then I was, you know, refining my design. I was like, hey.

Ed Sol [00:15:20]:

I remember that 1 knife and then, you know, got, you know, got on WhatsApp, called my my you know, called out Juanita. I was like, yeah, Juanita. Do you remember that one? I was like, Oh my gosh. Andy, I've been looking for that for 30 years. If you find 1, you'd let me know, and you buy, like, 20 of them because I don't know if they're gonna go out of business or what. And I'm like, Well, grandma, I kinda make knives now. She's like, well, you get good at it, and then you can send me

Bob DeMarco [00:15:44]:

one. Yes.

Ed Sol [00:15:46]:

Like, I don't want the first one. I want, like, the 50th.

Bob DeMarco [00:15:49]:

Preach. I love that. You know, grandma, like, don't don't You don't make me stronger by not sparing my feelings. So do you remember I mean, you're talking about cycling through, Walmart knives. There was a period of time, a long period of time, started with Ginsu where everything cheap was serrated, figuring that these people never sharp Sharpen their knives before they throw it out and come back to Walmart and get a new one. Yep. How did you, do, did you have those knives, and how did you deal with them?

Ed Sol [00:16:20]:

We would just basically sharpen the serrations off at knife. Like, I I now have an absolute hatred of serrations because of that. In my in my my current philosophy is, unless you're in the military and your knife your life depends on the knife cutting through that piece of rope To save you, you don't need serrations. Get off out get off your high horse, sharpen your knives. Alright? Like, we're done.

Bob DeMarco [00:16:46]:

Yeah. No doubt well, for me, I like them on, like like you're talking tactical knives and stuff like that. But on a kitchen knife, there is no place No place for that. So that leads me to geometry. You know? I got my first, I have 2 custom kitchen knives from the same maker, and I got them both within the year. And it's amazing to me that even when they're dull, they cut better than Yeah. Some of my, you know, or like the expensive knives that I have. So how do you approach, the the edge geometry and and the geometry Of the blade, you said that each knife has a specific, use or purpose.

Bob DeMarco [00:17:30]:

Do you vary, how you grind them and what the geometry is per use?

Ed Sol [00:17:34]:

Yes. So, basically, going back to sliceability, which has kind of been my focus, I like very thin, Very agile blades where there's less you know, basically, it's here's, you know, here's the sharp bits. The more you close it and get it thinner, The easy the less friction there is when you're slicing through things. So I try to make my blades literally as thin as I can close to the bottom and then about Halfway up, it'll kinda flare out a little bit more, and that'll kinda give you that resistance you need to, like, you know, get food released, things like that. But As close to the edge as you can, you want it laser thin, and that's what sets I feel like sets my knives apart is I like Steels that have very fine grain structures that are gonna hold a thinner, sharper edge longer. That's Basically what I shoot for.

Bob DeMarco [00:18:25]:

What steels are those? I'm sure you don't use the Apex Ultra on the on the,

Ed Sol [00:18:30]:

No, I'm going to, though. I I do have a couple pieces of Apex Ultra that I set aside to forge some chef's knives. But, my my go to steels specifically are in high carbon, a 50 to 100 and AEDL stainless. So my 2 I mean, I use anything the customer wants, but those are the 2 that I use the most because they are known for their very fine grade structure. You can get that just crazy fast.

Bob DeMarco [00:18:57]:

52100, isn't that the the NASA ball bearing steel? Yes.

Ed Sol [00:19:01]:

That's exactly right.

Bob DeMarco [00:19:02]:

How cool is that?

Ed Sol [00:19:04]:

And it's and it's awesome because, again, since they're in ball bearings, like, I I have chunks. So Between Indianapolis and Chicago, there is the I think it is actually the world's biggest wind farm. Oh. So I can just call up and be like, Hey, guys. By any chance, are you swapping out the bearings on anything? And if so, can I just by with a buck? Like, I will give you beer for your old ball bearings. And they're like, Yeah. Just don't come on Thursdays because that's when the supervisor's here. Any other day, just call this number, say, ask for you know, I'm not gonna give the guy's name, but ask for so and so and I like Coors Light.

Ed Sol [00:19:42]:

Wow.

Bob DeMarco [00:19:43]:

That is so cool. So that how big are those bearings? I mean

Ed Sol [00:19:46]:

They're enormous. Like, the rings are about, See, I'm trying to get these little camera, but they're about as big as my head. Wow.

Bob DeMarco [00:19:53]:

Yeah. That's that's pretty cool.

Ed Sol [00:19:55]:

And I cut them in in the, like, it's a sliver, like One of those pairings will make 20 plus knives.

Bob DeMarco [00:20:02]:

And then and then okay. So so I would imagine so if you Start making, okay. My my brain is get getting ahead of me. For kitchen knife making, I would imagine that the forging process, unless you buy plates of steel that are very, very thin, the forging process is gonna be more efficient And maybe an easier way for you to get to, a real thin stock to start with. Is that right?

Ed Sol [00:20:31]:

Yes. So that yes. So basically, again, you have the giant ring, and it's about that thick, so about 4 inches Why it is how thick the bearing is, I'll cut a, you know, quarter inch, sliver off that whole thing, and I can just heat it up, and from there, I've got a beautiful starting position to draw out make the blade, and it's, I've got a hydraulic press and a tire hammer, so it's like, it takes me less than a beer to get the rust shape in.

Bob DeMarco [00:20:59]:

Okay. So your knife making skills and capabilities really did come out of a a blacksmithing, beginning. Right? Yes. What is what is the difference? I forget that there is a difference, but until I see them next to each other.

Ed Sol [00:21:16]:

So You mean between, bladesmithing and stock removal?

Bob DeMarco [00:21:20]:

Well, no. No. No.

Ed Sol [00:21:21]:

No. I'm and bladesmithing.

Bob DeMarco [00:21:23]:

Yeah. Isn't a blacksmith also, Or is the bladesmith also a blacksmith? How does

Ed Sol [00:21:28]:

that work? Basically, the umbrella would be blacksmithing, which is basically Heating up steel and hitting it, and then a subset of that would be bladesmithing. So there's all these skills that encompass making things out of pot steel, And then just a portion of that is bladesmithing. So, again, I didn't know what I didn't know, so I started learning all of the basics, And I have a pretty big toolset that now when I need to make something or teach somebody how to do something else, I know how to do it because I'm self taught, and I I went to YouTube University and learned how to do it.

Bob DeMarco [00:22:02]:

That's the best university out there these days. So a a, a blacksmith is someone who Makes tools or art with Yes.

Ed Sol [00:22:12]:

Tools, decorative, staircases, scrollwork. They were basically the go to guy of the old west. For example, they make s the I don't know if you've heard of the s books, it gets a steel s. It's called a cowboy duct tape, because that you use it for everything. Yeah. You need to make it something close. You need to get your pot close to the fire, add a couple s hooks, hit it lower. Things getting too hot, you take a couple S hooks out, get it away from the fire, the chain doesn't reach to wrap it around something, add a couple S hooks, You know, it's used for everything.

Ed Sol [00:22:45]:

That's one of the things I love about blacksmithing is you don't know how how useful it was Because it did everything. Like, you couldn't go to the, you know, you couldn't go to the store and buy it. You had to call up the guy and be like, hey, can you make me x y z? And then have him walk you walk you into his schedule.

Bob DeMarco [00:23:04]:

Yeah. Chances are you didn't call him at all. Chances are you

Ed Sol [00:23:08]:

Yeah. You walked over there.

Bob DeMarco [00:23:09]:

Yeah. Yeah. That's, I I love the idea of a community blacksmith, community knife maker. I know in Japan, that's a that's It's always been a tradition, you know Yeah. As well. I'm sure everywhere that uses metal, but the idea of also having a knifemaker, someone particular.

Ed Sol [00:23:29]:

Yeah. So like I said, I'm in rural Indiana, so the amount of farmers that just drop by, I'm like, hey. You weld this thing back together, and it's like, yeah. Like, let's do a throw I've got a ginormous forge that's open on both ends just so I could put farm equipment from both sides to get hot enough to forge weld itself back together. I sharpen lawnmower blades that are big, you know, Like industrial sized lawnmower blades, or I don't even know what it is, but it's a lawnmower blade on steroids, I sharpen those 3, 4 times a week, like, just every guy is, like, hey, Eric, can you can I borrow your shot for 20 minutes or an hour? I need this done. I need that done. Because it's one of those things, like I said, they'll show up and they'll give you beef, they'll pay me an eggs, they'll pay me an egg. Oh my god.

Bob DeMarco [00:24:18]:

How cool.

Ed Sol [00:24:19]:

Yeah.

Bob DeMarco [00:24:19]:

So That is you. You are the community blacksmith.

Ed Sol [00:24:22]:

The guy.

Bob DeMarco [00:24:23]:

And and it's still relevant. That's amazing. I love that because, Yeah. I I mean, I didn't grow up in a farming community. I don't know from farming, but I love the idea that all of that stuff has to be, you know, Eventually, it all has to be fixed. Yeah.

Ed Sol [00:24:38]:

And, you

Bob DeMarco [00:24:38]:

know, I guess you could send it back to the manufacturer or You could go down the street to the blacksmith.

Ed Sol [00:24:45]:

Yeah. So like I said, so the like, I don't even know what it is, but it's one of the structural beams, Like, they bolted off a tractor or harvest or whatever and it was like $9,000 to mail it back, get it fixed, and then have them mail the exact same back, or they brought it to my shop and gave me, you know, a cup you know, a, you know, a couple 6 packs and 2 dozen eggs, And we've heated it up. I made a what's called a scarf fold where it basically hooks onto each other like this and just, you know, bathed it, make sure it fit it was dry fit, And we put in the forge, you know, baptized it in flux, got it white hot, hit it a few times with a hammer, Let it cool down, sprayed it with barbecue, high temp spray paint for them, put it back on the track, the harvester, and he's saying it's harvesting corn. 2 hours, which could've been would've been freebie so he could've used the tool if he'd shipped it off.

Bob DeMarco [00:25:40]:

That's pretty amazing. I wonder how many, You know, I I I talk to a lot of knife makers, obviously. Some of them forged, and, I I wonder how many people could Bend their, their shop to do such a thing. It's a it's a great idea to me. Also probably a great way to make Extra cash as a knifemaker.

Ed Sol [00:26:01]:

Yeah.

Bob DeMarco [00:26:02]:

But but I love that. I I I think I have a lot of nostalgia for times I didn't in places I didn't grow up in, and that to me, Yeah. That's, that's cool. Another concept similar to that that is also very interesting to me and is something I I really hope we all go move back towards a lot more than we are right now is apprenticeships. Now we were talking before about your apprenticeship with Todd Hunt, custom knife maker, TM Hunt. Tell me about that and and, like, how you see The benefit what the benefits of apprenticing are and how this is working

Ed Sol [00:26:39]:

for you. It's been amazing. Like, it's it has changed my knife making Career. Like I said, I was self taught, and thankfully, like I said, I have a very supporting family, And my wife gets it. So she's letting me say, I can call I mean, as long as the kids are home and everyone's sad, I'm like, hey, sweetie. I wanna drive to Kentucky, I wanna drive to Pennsylvania for the weekend, I'll be back Sunday. I'll let you know when I get there and just hang out in people's shops To learn, and it's like I said, it's always been somewhere far away. But then, I I I stumbled across Todd Hunt, who is literally in Seamort, just about an hour away from me.

Ed Sol [00:27:20]:

Fantastic. It's a fantastic knife case. I kept trying to, like, reach out, like, hey, buddy. You're only an hour awake. Like, again, can't, you know, let me be a fly on the wall. Can I come over? Can I hang out? Can I, you know, I'll bring Mexican food, like, you'll love it? Let me just let me hang out, pick your brain. But he's a productive production knife shop. He doesn't have the time.

Ed Sol [00:27:40]:

And then, he moved out of his home shop into a bigger facility and was at the point I mean, he's very like, he's he's earned it, but he's at the point where he can he needs help making his knives To, basically, to meet the demand that's out there for his product. So he needed help from someone. So I was like and I the second he said that, I was like, dude, it's me. Just let just let me come over. I'm not a psychopath, I swear. And, basically, he had me over one day, interviewed me, had me bring my work because, You know, he didn't want I mean, he needed somebody, but he didn't have the time to train them. So he's like, even if they're halfway decent, I could bring them up to where I need them to be. And then so I brought all my knives and he thankfully, they were better than he expected.

Ed Sol [00:28:33]:

So the the the the bar wasn't too low, but yes. So he's like, hey. You know how to use all the tools. I love your creativity. All you need is practice, and my goal is to teach you to make my knives And bring, you know, your game from here up to here. This is where I need you to be, and that's what we've been working on. Like I said, grinding techniques, finishing techniques, ways to be more productive when I'm making my batches of knives, you know, Things I should be focusing on, areas to like I said, it's just it's been a he's been an absolute blessing in my life. It's just really been amazing.

Ed Sol [00:29:08]:

Very grateful to him, Spencer is also down there.

Bob DeMarco [00:29:13]:

Definitely, your perseverance got you in, though, and and that's something people need to remember. Yeah. Especially today with, people especially maybe younger people who are not as comfortable With other people. Yes. You you really have to be persistent and, people recognize that. I mean, I I tell my my daughters this All the time, you know. You you you're very persistent when you want ice cream or when you wanna watch something or whatever. You need to be that persistent about what you want out out there in life because, eventually, you'll annoy people like you annoy me and they'll give in.

Ed Sol [00:29:49]:

I heard a fantastic quote that I've really been that really resonated with me, and it's the magic you're looking for is in the work you're avoiding. Yeah. So I mean and it's you know, like, if you look at Brian House, hard work leads to good luck. Like, it's As long as you keep, you know, doing what you need to be doing, you're gonna get there. And it's that's the beauty of the apprenticeship is I have the drive. I just didn't have know where my destination was, and Todd has been there. Like, we need to get you here. Here's how we're gonna get there, and that's the beauty apprenticeship is as long as you put in the effort and actually listen to the advice given, You're gonna get better.

Ed Sol [00:30:35]:

Like I said, it's I'm I'm set up happy, blessed out in my life.

Bob DeMarco [00:30:41]:

It is, apprenticeship is truly, what's that? Symbiotic because Yes. He he needs someone, And he needs someone good, and he needs to make that person good in his own image, so to speak. And you need to become good for your own work And and also to do a good job for him. So everyone benefits. Let's let's talk about your knives.

Ed Sol [00:31:06]:

Okay.

Bob DeMarco [00:31:07]:

You just showed me that kitchen knife. Hold hold that back up for a second if you will. Absolutely. So I love the, First of all, the blade shape is pretty interesting. It reminds me a little bit of what I've seen from, Vietnam, Vietnam, style kitchen knives. But I love that, nice circular choil you have to lock your finger in

Ed Sol [00:31:28]:

Yes.

Bob DeMarco [00:31:28]:

Right there at the Ricasso. This is a this is a beautiful knife. I'm I'm loving this.

Ed Sol [00:31:35]:

Yeah. And like I said, it's just been repetition. For example, they used to be a lot Thicker, but now if you look at it, I mean, it's just razor thin. Yeah. And then you added the finger, at some point, I, It's like I don't like how I'm holding it. I wanna get the a finger choil, so now everything gets that finger choil, and it's just got that beautiful pinch grip. So when you hold it, it's got a contour, Contour handle that just needs that paint grip, and it's like I said, it's surprisingly light, which is, again, another benefit, because it I mean, obviously, us home cooks, we're not gonna be processing veg for 8 to 10 hours. Right.

Ed Sol [00:32:12]:

But there are people who are out there and, again, Wanting to make the best tool possible. If I can make it that much lighter, why not? Because you can make it the best tool and the chefs out there dig it, Then, you know, that's that's only a benefit, and it's and it's gotten to the point where I go to chef I same thing, I go to chefs, I go to professional patients. I'm like, hey. You know, can I talk to you 1 morning, get your opinion on things as I was starting today? That was one of the things that they brought out is it needs to be light, it needs to just be As thin as humanly possible and just something I can use all day and I don't feel the carpal tunnel after a couple hours because it's such a big, heavy chonker, Which, again, if you buy those big, you know, like, again, going back to Wusthofs and Cutco knives Yeah. They're just really thick and heavy because they only have a grind about, you know, a third of the way up, and then it's 3 16ths at the spine. I mean, it's I mean, for example, in my household, I know I need to sharpen our kitchen knives because my wife grabbed a cut coat, so that's that's the red flag right there. I was like, uh-oh. Yeah.

Ed Sol [00:33:17]:

Yeah. I need I need I'll be right back,

Bob DeMarco [00:33:19]:

baby. Yeah. Yeah. Don't do that to yourself. I'll be right back. So is the heat treatment, very much different when you're making a kitchen knife? I I I imagine you want since you're cutting against wood, and I would imagine you want, somewhat high, Rockwell hardness. Yes. But at the same time, you know, in a kitchen, you're banging into other metal and you're doing stuff and scraping and stuff.

Bob DeMarco [00:33:44]:

You also don't want it to be too brittle. How do you handle the the heat treatment for

Ed Sol [00:33:48]:

kitchen work? Testing. The answer is testing. My wife, although she's very supportive of my knife making, she doesn't get it one bit. She's like, you you charge how much for these things? They're like, really people pay you? I'm like, honey, the market just paid, baby. Like, it works. So she is the best person to hand something to be destroyed because I will give her I will give her a knife. I'm like, here, honey, just use it. Let me know what you think.

Ed Sol [00:34:16]:

0 less given. Like, it it goes in it goes in the dishwasher. Oh, yeah. She just slams it in the drawer. Or heck, like, I've Again, I understand it's for a family her family thing. They love to chuck things, so she'll just yell at our kids, hey, open the knife drawer, and she'll just chuck the the the kitchen color, and I'm like Like, honey, that's expensive. Yeah. I'm gonna sell that, like like a little bit of love.

Ed Sol [00:34:40]:

And she's like, nope. She's like, You asked me to test it. This is what I do with our kitchen knives. Like, this is why they're all banged up. That's why we don't have nice things.

Bob DeMarco [00:34:46]:

Well, actually, that she's doing you a huge favor because That's how chefs that's how professional kitchens are too. It's like everything's metal. Like, you know, the the kitchens I worked in, the bain marie, everything's metal there, and then the table, and then you just have a cutting board. You done cutting? I I was a prep I was a I did tons and tons of veg veg prep, and I used to do that, you know.

Ed Sol [00:35:10]:

So that was it. So I've just as I practice because, again, you just keep fine tuning your your heat treat recipe. Specifically, like, 50 to 100 has a multistep process to get the most out of it. So you have to do 3 sets of normalizing and grain reduction of 3 you know, it's 15 minute soaks at 3 different temperatures, and It's a whole and you have to let it come down to a certain temperature before you ramp it up to the next one. So it's a whole thing, but once I've again, I've got time. So, 1 knife out of every batch, I'll just do it slightly different and then it's, you know, when it's done, it goes into testing, and then after 6 weeks of abuse by my family. If there's no dings or scratches or anything, I'm like, oh, okay, this works. Do I like it better than what I'm currently doing? Yes.

Ed Sol [00:35:58]:

No. And if I do like it better, well, everything else gets done that way. And if not, well, what can I do differently on the next one to try to bring everything up? And that's, like, for that's how you do it.

Bob DeMarco [00:36:10]:

That's a that's a pretty, meticulous process. I I admire it, and, You know, that kind of process does take a little bit of discipline. Sometimes creative people can be impulsive and And, but it's interesting to see how creative people can also become scientists, you know, when they're doing something they love like, You know, like knife making.

Ed Sol [00:36:33]:

Yeah. Well, that's the beauty about having ADHD is I when I have something something grabs my interest, I hyperfocus on it And I consume the knowledge, like, at a free straight, so I'm always excited to to see how I can do better. Like, now I'm at the point where It's something he treated and, like, the belt, you know, the belt grinder grabs it, checks it into the wall of the concrete. I don't care. I know the tip's fine. Like, you know, people always like, oh, cringe, it's gonna be broken. I snapped 50 plus blades at this point just to see what the grain looked like. I know if it got shot across the room, the tip's fine.

Ed Sol [00:37:09]:

Why worry?

Bob DeMarco [00:37:10]:

Hey, dude. If it's shooting knives across the room, like, the last thing I'm worried about is the tip of the knife.

Ed Sol [00:37:16]:

Yeah. Exactly.

Bob DeMarco [00:37:17]:

It's more like where is the tip of the knife? So, with the with your process, When you acquire steel, are are you are you someone who goes out I mean, I know that you get the 52, 100 from, From the wind farm and stuff like that, but is that how you get all your stuff minus the Apex Ultra?

Ed Sol [00:37:39]:

It it depends. If I can find A recycled version of it to use, and I don't have to worry about, like, micro fractures or things like that. I will do it that way. But honestly, the best way to get AEDL, for example, is to buy it out of bar stock. I just haven't found something that's out there in a large enough quantity that I been processed by means, but, a lot of, for example, my my ferry arrest I use for tomahawks, those are made out of a version of 10.95. I have a a farrier out of West Lafayette, Indiana. I basically pay him and beer to spend the extra 20¢ to get an American made file that I bait. I called the manufacturer, Hey.

Ed Sol [00:38:23]:

I need to know what steel this is that you're using for this new set because I'm a blacksmith, and, basically, I told them that I want my favorite friend to use it. He basically said, I have a guy that's gonna be your customer if you tell me what's in them. And like, yeah, here's, you know, here's a steel composition. It's exactly 10.95 Plus, you know, 1% manganese and 2% whatever. I was like, oh, perfect. That works. And I basically turned around, and I'm like, Larry, I need you to buy these. I was like, oh, about 3.20¢.

Ed Sol [00:38:50]:

I'm like, dude, I'm a give you a case of deal when you fill up the 5 gallon bucket. Stop your complaining. You're getting paid. He's like, oh, I guess so. And it's and I'm like, plus, it's American made. You know? We're a little businessmen. Let's help this other little businessmen. We all do better.

Ed Sol [00:39:05]:

He's like, Fine.

Bob DeMarco [00:39:07]:

Yeah. Yeah. Nothing like a little guilt to

Ed Sol [00:39:09]:

to get people out of it. Yeah. And that's how I do and that's how I get 50 my, 10.95. 51/60, I there's a local junk there's a local, car junkyard. I showed up with some roller spikes, knives, and some bottle openers, I'm like, hey, I'm a blacksmith, here, this is what I do, can I have some 51.60? And like, Yeah. Well, you know, because again, with leaf springs specifically or coil springs, you don't want them off of an old, you know, 52 truck Because they're gonna be micro fractures. It's you know, the car's been rung for 50 years. It's, you know, it's trash, but the the amount of people who Truck you know, tow a brand new truck is, like, once a week.

Ed Sol [00:39:54]:

So they're like, hey. We have this guy tow the brand new truck, like the leak like, the car's got A 100 miles on it. Do you want the leaf springs in the coil system? Yeah. He's like, I set him aside. Come on up. Pick him up whenever you want. I'm like, alright.

Bob DeMarco [00:40:08]:

That's, man, that's a great supply. You've you've got it's not it seems like you've got your fingers kinda you got lines in the water everywhere.

Ed Sol [00:40:16]:

That's what you gotta do. So

Bob DeMarco [00:40:18]:

So this this leads me to, you are on Forged in Fire as I mentioned in your intro. Did Did that instinct and these resource yeah. This resourcefulness, did that come in handy on the show? And tell me about your experience.

Ed Sol [00:40:31]:

Yeah. Oh, yeah. It was so I I messed I mangled so many things while I was on the set. Like, it's like and again, one of the things I I and I love this show. It's so much fun to watch. I watch it like it's football, So like you're constantly strategizing, don't fixate on one thing, be ready to pivot as, you know, as things go horribly wrong, Don't just because again, the worst thing you can do is freak out and just stop. Like, you're on a clock. You gotta get it done.

Ed Sol [00:40:58]:

And, like, The amount of things that got after them fixed was this is a whole show. Like and then the worst part is you're like, okay. So this is messed up, like for example, I would quench the blade and then I was grinding it and I made it too short, so that'd go back to the fire to draw it back out So they're inquiring to make sure I've met the specs, and then you just hear David Baker. I was like, That's a new way to do that. Eduardo came up with a really interesting solution. I'm like, don't do that to me, David. I got like, like, you're making me second guess my whole life right here.

Bob DeMarco [00:41:30]:

So you can hear everything when you're

Ed Sol [00:41:32]:

Oh, yeah. That's the thing is, because you your hyper because they're, what, like, they may be, like, maybe 10 feet away, but They are they're they're they're the experts. Like, they literally are holding your eyes in their hands. So every time they say something, like, we would all kinda Slow down and play it down a little bit to hear what the the conversation that's going on. Oh, they didn't talk about me. I said, okay, keep going, keep going.

Bob DeMarco [00:41:56]:

Wow.

Ed Sol [00:41:56]:

But then, like, oh, What's it all doing now? And you're like, what what am I doing? Like, like, like, give me more information here, David. Like, do I need to stop? Do I need to pivot? And it was but it was a hoot because again so my episode was The Gaucho's Revenge is, what what what it was called, And it was really funny because during the interview, like, I go by Ed's Ed because it's easier to say than Eduardo de Jose. So they're like, oh, we like it, Eduardo. We're the kind of Eduardo. Is that okay, Eduardo? I was like, tell me what you want as long as I get on TV. Like, I'm in. And, long story short, they fly me out there and said, Eduardo this, Eduardo that. I'm like, why? Like, why are they suffering to say my name right? I get on the set, and I just see sarapes, sombreros, a wood fence.

Ed Sol [00:42:45]:

Oh my god. They called in the they called in the white Mexican as a ringer. And I was like and then, like, in the, like, in the guy, Grady was there with the hay in his mouth. I'm like, dude, this is gonna be the most racist episode of horse and fire. And like I said, then the second they pulled that tire up and I saw that gaucho, I was like, oh, like, I got this. This This is this is mine to lose.

Bob DeMarco [00:43:07]:

So a gaucho, what is that?

Ed Sol [00:43:09]:

The the first knife was a gaucho's knife, So it was basically, sand mide construction. So it's, hard, steel in the middle and then 2 soft steels on the side, But it is basically like a very large chef knife that's thicker that's meant to be used out in the field for The Gauchos are basically the Argentinian cowboys, and they use those knives for literally from cooking to skinning the animals To cutting through rope, it's their it's their sesamie knife. It's 1, like I said, it's like a usually, like, 9, 10 inch, chef knife like blade, And it's just like I said, it's just the way you heat treat. The heat treat is what's different on the Godzilla. Think of it as a giant kitchen knife is the best way to put it because it that's what it looks It looks like a triangular chef knife, just oversized, and it's

Bob DeMarco [00:44:03]:

They remind me a lot of French Fighting knives from, I don't know, 18th 17th, 18th, 19th century, that That also looked like chef's knives

Ed Sol [00:44:15]:

Yeah.

Bob DeMarco [00:44:15]:

And where they famously used the the width of the blade as the guard, you know, so, Yeah. Which which is efficient, and it also creates a really broad blade that if you're using it, to slice and to cut and to do these kind of things around, the camper in the field, it's very efficient. And if you're using it to to stab into someone, You're making a big hole, so, I mean, they're Yeah. They're very efficient tools, but but look very pedestrian in a way.

Ed Sol [00:44:44]:

Yes.

Bob DeMarco [00:44:45]:

So how did you do on that?

Ed Sol [00:44:47]:

I made it to the finals. So, At the very end, they give you the sword the the the final challenge you have to make, and I asked, hey, can I see the blade Because I wanna, you know, in my mind, take measurements to then make that exact blade? Because if I make the blade you hand me, It's gonna be perfect. Right? So they bring out the blade, and I'm measuring everything. Like I said, I'm I it is the curse that now everyone knows I have small girly hands because people go to my like, oh, Ed. Nice to meet you. Great. Like, oh, I see why you lost. Yep.

Ed Sol [00:45:24]:

Yeah. You got little hands. Because the handle was literally my hand plus a finger. That's how I measured the handle on the knife that David Baker made. So When I and that's the one thing that on the on the instructions, there was no criteria for the handle. It just said make a handle, so I was like, you know, if I make this, I'm good. Well, David Baker has normal sized hands, but Doug Markaida has a handsome proctologist. Oh, he grabs my knife.

Ed Sol [00:45:54]:

He grabs my sword, and he grabs, like, a 3 finger knife. He's got 2 fingers. Like, this third one's, like, pinched in and the pinky's, like, way out here. And I was sick, and I saw him down. I'm like, oh, no. No. But it's it is what it is. They say that because, again, you don't you're not allowed to meet the judges until after you're disqualified, and then when I went to shake their hands, like, thank you for the experience, and this mammoth hand just Comes like just sausages, and I'm like, oh my lord.

Ed Sol [00:46:23]:

Like, I've never felt like a smaller human being until Doug held my hand because it's like basically, it's like when I hold my 11 year old daughter's hands. Like, oh, look, she's adorable. See her, I love you. Be safe. Wow. I don't shake his hands. Like, it's he's like like it's like, yes, he's a trained martial artist, and it's one of his handshakes is, like, Brain damage, like, it's enormous. Yeah.

Ed Sol [00:46:45]:

So when I saw that, I was like, ah, I'm I'm going home. And it was one of those things where I talked to the judge after the wife's like, dude, we would've Loved to see your blade perform. Like, it was so sturdy. Like, it would have done so well, but Your handle now is like, listen, Dave. That ain't on me. That's on you. I mean, your handle, and he's like, well

Bob DeMarco [00:47:08]:

Well, sucks to be here.

Ed Sol [00:47:10]:

It is. I I had a great time.

Bob DeMarco [00:47:11]:

How did you get involved with it? Were they doing a casting call and you just

Ed Sol [00:47:16]:

Ironically, Forged in Fire is like time shifts. They say, hey, you had a great time listening to our presentation. Could you give us the name of 10 friends that you think would enjoy this presentation too, and enough people put my name down, like, dude, you need Ed. He's hilarious. He's gonna be great TV. Gave him a call, and then I have literally I don't know. I think I just found I just got, like, over 40 of my buddies that have been on the show. I'm like, yeah.

Ed Sol [00:47:44]:

I told them to call you.

Bob DeMarco [00:47:45]:

I was

Ed Sol [00:47:45]:

like, well, they called and thankfully, we think we were able to work something out. But eventually, I'm hoping to go back for a redemption episode they had. I was in Moses about this summer, but they never called back with a with a with a flight date. So

Bob DeMarco [00:47:59]:

Well, they're they're pretty smart because, I I believe that that show generates more, bladesmiths. You know, with every season, there's someone who gets into it. I mean, I used to work in the fashion industry on the on the production video production side, and, We my wife and I used to watch Project Runway.

Ed Sol [00:48:19]:

That's another great show.

Bob DeMarco [00:48:20]:

Yeah. And I was like, someone needs to do this, but for knives. Yeah. And my wife's like, dream on. And so and then, you know, years later that came out and and it's our

Ed Sol [00:48:29]:

favorite thing. And it's been on for 10 years at this point. They're on season 10. I think they're Starting to tape for season 11, so they've already created their own fan base and the pool to then pull more knife knife makers in. Because, like, my kids, they're in the shop all the time. Like, they love making knives. Like, they make fantastic railroad spikes. They make tomahawks.

Ed Sol [00:48:51]:

They make bottle openers. They make Little artsy peeps to take you to the pool. And at this point, I'm like, if I especially like with my 8 year old, I'm like, dude, I could Sign him up now for the ABS, and he could and if if it's just a little bit of a nudge, he could probably test her journey 2, 3 years. I've just been an 11 year old. Wow. And it's one of those things, but then again, on the opposite side is my wife's like, I've seen your hands. Like, we're not doing that to a small child. It's fine, baby.

Ed Sol [00:49:21]:

Like, it's it's like, what are scars?

Bob DeMarco [00:49:24]:

Well, yeah, exactly. Well, I saw a Really cute video on your, Instagram of a daughter of yours, you know, pulling pulling a piece out of the out of the, Out of the forge and then walking over to the power hammer. Oh, look. Yeah. That is that just warms warms the heart out

Ed Sol [00:49:41]:

of the way. What they love to do. Like, they don't Like, not that I don't encourage them to be couch potatoes, but that's something that we care about, so they It's not really an option. So they're like, yeah. I can watch something you do on TV. Like, my dad's got a full metal in woodshop. Like, I could make that. And they're like, hey, dad.

Ed Sol [00:49:59]:

Do you wanna make an x y z? And it's like, Alright. Let's go. You know, we make birdhouses for bats. Like, right now that it's getting colder, we're making Houses for stray cats to survive the winter. It's like whatever they want. Like, it's like, let's go.

Bob DeMarco [00:50:14]:

You know, that's that's a bigger gift than you might imagine. Hopefully, it isn't. But I mean, that self reliance Yeah. Is gonna come in handy in their lifetime.

Ed Sol [00:50:25]:

And it's that self confidence because they're learning a skill and they they're creating their own value because I don't want them to think That their value in validation comes from somewhere else. That's something that I struggled with personally growing up, so I know the value of Being self aligned, like they could say, Hey, I might have a hard day today, but I'm a good person. I can do X, Y, Z, And then they have those tools for later. Like, my son is he's a both of my kids are angels. I love them to pieces, and they have such good hearts. My son will come home with these random toys that I've never seen him hold before, and they're broken. And then he'll just kinda like, hey, Dex. Can I borrow some superglue? It's Alright.

Ed Sol [00:51:07]:

And he'll come down here, grab some SuperBoo, and he'll glue these little toys back together, and then they disappear again. I'm like, what happened? Oh, well, you know you know, that was, You know, Erez' toy, he broke it. His dad didn't know how to fix it, so I I saw that he tried using this superglue, and it was the wrong thickness, so I used a combination, You know, JB, well, I'm like, that's actually really smart how you did that. He was like, well, it worked, so I fixed the arrow's toy and so I just gave it back. I'm like, Okay. Yeah. Yeah. That's awesome.

Ed Sol [00:51:37]:

And that's how the email. Like I said, that that self worth, nobody can take it away from. It's like, I fixed my friend's toy all by myself. And that's only gonna improve, like I said, his self, you know, his confidence and his relationship with that kid. So

Bob DeMarco [00:51:52]:

Yeah. The the older I get, the more I see in in my peers and and just, well, I noticed this a lot in men. Women can't help but be useful, but men, all they really want is to be useful In some way or another, and, oftentimes for men, it happens to be building things or fixing things. Yeah. And, that is a great way to show your your worth, not only to other people, but to yourself. Like Yeah,

Ed Sol [00:52:21]:

absolutely.

Bob DeMarco [00:52:21]:

If you're down about yourself, like you said. Yeah.

Ed Sol [00:52:24]:

Like, doesn't matter how rough of a day I have. Like, I can look at my bench and I can see the things I've made in my hands and it's like, that's the best I can do, And it's gonna go out into the world, and someone's salmon's been appreciated it for literally a 150 years. And the The reason I say 150 years is because the weakest leak in my weakest link in my knife is the epoxy on the handles, which has a shell, Which will only last 150 years.

Bob DeMarco [00:52:50]:

Yeah. So

Ed Sol [00:52:50]:

I'm currently experimenting with other adhesives that'll give me a longer life on my handles, So my knives will last longer. Yeah. Because, again, when I'm dead, I'm dead. But I want the things that I create to be out there.

Bob DeMarco [00:53:03]:

Try tree sap. You know, some of these old, Filipino knives, they're they're they're banging strong, and they're old. You know? Yeah. I mean, I say that half facetiously, but, yeah, it's amazing. You you don't know what you don't know what traditional things you might return to, that That might, you know, lead lead to new new answers. What well, first of all, I gotta ask you. Have you heard of the Texas Custom Knife Show in Yes. In Conroe, I'm gonna be there this year, and it it it it's really built around guys just like you who have been on Forged in Fire.

Bob DeMarco [00:53:39]:

I know it's expanded to beyond that, but that is a big a big part of it. I, are you gonna go to that this year?

Ed Sol [00:53:47]:

Not this year. I it's just not. I just don't have the time or the budget for it, but the goal is hopefully next year. I'm really pushing my desire slash, the desire's always been there, but I'm pushing my production. Saying again, going back to, Todd Hunt, he's really gonna help me increase my production, how much I can make per batch. So my goal is next year, like, I wanna go to the Texas Custom Knife Show, I wanna go to Blade Show West. Those are the 2 big shows I wanna add To my calendar, I just have to make, you know, make enough knives to just be able to afford to go and then hopefully, because, again, I don't wanna go to a show and then say, oh, I need to sell 30 knives here just to be able to afford to go home. Yeah.

Ed Sol [00:54:34]:

I'd rather say, hey, I've I've got enough money that I can get there and comfortably come home regardless if I sell some knives.

Bob DeMarco [00:54:42]:

Oh yeah, yeah, definitely. I mean, You don't you you don't want to endanger your life for something like that, but but, it it is, I'm very excited about it. It's a it seems like a really interesting, show and I'm excited to meet Doug Markajda in his massive hands and and Jay Nielsen, who I've had on the show before and is a a really

Ed Sol [00:55:02]:

cool Amazing.

Bob DeMarco [00:55:04]:

God, he is amazing.

Ed Sol [00:55:05]:

They asked, so they asked, like, hey, are you a fan of this show? When I was in there, I was like, dude, I love everybody on the show. I'm a huge Shane Nielsen fan. Like, I actually own all of his DVDs for knife making. Wow. And they're like, dude, they're like, are you zapping for I'm like, listen. If you let me get on the show and Jay is my judge, like, I will literally show up with a Sharpie so he can sign my man, dude. That's how big of a fan I am. Like, I I love Jay.

Bob DeMarco [00:55:31]:

Now that is a fan.

Ed Sol [00:55:32]:

Yeah.

Bob DeMarco [00:55:33]:

Where where, where do you wanna see, Ed Saul Crafts? Like, how how do you wanna evolve, your, your company, what what are your goals?

Ed Sol [00:55:44]:

Basically, like I said, I'm a very small fish in a very large ocean of knives. I just I just wanna keep being able to afford to do what I'm doing, cover my bills. Like I said, I I'd like to grow And just expand like, just expand my lineup, use more exotic materials, I'm actually starting to work on some folders, believe it. I've I've made slip joints, and I've you have really been driving me to go back to that because It is an exercise in patience to make a slip joint.

Bob DeMarco [00:56:23]:

I bet.

Ed Sol [00:56:24]:

But I'm also, with Todd. We're we're we're, gonna be tackling, some flippers in the very near future, so that's really, my goal is Just keep chugging along, making cool things, and having people appreciate it. Like I said, I don't I don't do this to get rich. I do this to spend Be able to afford to spend time with my family, you know, live comfortably in the middle of Indiana.

Bob DeMarco [00:56:51]:

I love that. And and be the The town blacksmith and and the and the fixer.

Ed Sol [00:56:57]:

Yeah. Just I I'm I'm slowly turning into a pillar of my community, and It's it's nice. I like that feeling of being needed by my neighbor and just being able them being able to call me and be getting somebody out of the bind. Like, I love, like I said, going back to, I like being appreciated, I like being helpful and it's just being a good person. I have the flexibility to help people in a tough spot and I love doing it. That's really what it's all about. It's life's life. I'm gonna be here for a short amount of time.

Ed Sol [00:57:25]:

I wanna leave the book just a little bit better than when I got here.

Bob DeMarco [00:57:29]:

Well, Ed, thank you so much for coming on the Knife Junkie podcast. It's a beautiful way to end. Ed Sall of Ed Sall Crafts, thank you so much, sir.

Ed Sol [00:57:37]:

Thank thank you for having me. I had an absolutely fantastic time. It was great talking to you.

Bob DeMarco [00:57:41]:

My pleasure. It was my pleasure speaking with you, sir. Take care.

Announcer [00:57:45]:

Looking to amp up your self defense skills? Meet the Shockwave Tactical Torch. It's your ultimate tactical flashlight for safety in any situation. With a long lasting LED bulb, this bad boy also packs a whopping 4,500,000 volts. Picture the confidence of having this by your side. A quick flash stuns any threat. Best part? It's easy to use. Just one click and you're safeguarded. Don't risk it.

Announcer [00:58:10]:

Get the Shockwave torch now and embrace ultimate protection. Get yours now at bit.ly/shockwavedashtacticaldashtorch. That's bit.ly/shockwave dash tactical dash torch.

Bob DeMarco [00:58:22]:

There he goes, ladies and gentlemen. Ed Sall of Ed Sall Crafts. I'm really a big fan of his collaboration knife and his hunting knife that I left right over there. I do look forward to checking out more of his stuff in the future. And be sure to to check out episode, I think it was I should have asked him. Season 8, episode 9 Or season 9 episode 8, I can't remember. Look at them both. I'm sure they're both awesome.

Bob DeMarco [00:58:49]:

For Jim working his magic behind the switcher, I'm Bob DeMarco saying, until next time, Go take doll for an answer.

Announcer [00:58:55]:

Thanks for listening to the Knife Junkie podcast. If you enjoyed the show, please rate and review at review the podcast .com. For show notes for today's episode, additional resources, and to listen to past episodes, visit our website, the knifejunkie.com. You can also watch our latest videos on YouTube at the knifejunkie.com/youtube. Check out some great knife photos on the knifejunkie.com/ Instagram, and join our Facebook group at the knifejunkie.com/facebook. And if you have a question or comment, email them to Bob at the knifejunkie.com or call our 247 listener line at 724-466-4487, and you may hear your comment or question answered on an upcoming episode the Knife Junkie podcast.

Share This With a Friend >>>

For early access to The Knife Junkie podcasts and YouTube videos, receive Knife Junkie stickers and be entered into the monthly knife drawing giveaway, join The Knife Junkie’s Patreon group of awesome supporters.

Let us know what you thought about this episode. Please leave a rating and/or a review in whatever podcast player app you’re listening on. Your feedback is much appreciated.

Please call the listener line at 724-466-4487 or email bob@theknifejunkie.com with any comments, feedback or suggestions on the show, and let us know who you’d like to hear interviewed on an upcoming edition of The Knife Junkie Podcast.

To listen to past episodes of the podcast, visit theknifejunkie.com/listen.

Shopping for a Knife?

Support The Knife Junkie Podcast and YouTube Channel by Buying Through My Affiliate Links

Amazon

Amazon

Angle Pro Knife Sharpener

Artisan Cutlery

Bamba Forge

eBay

James Brand

Knives Ship Free

Off-Grid Knives

Vosteed Knives

WE (Civivi) Knives

Other Products and Services

1Password

16-in-1 Multipliers

Free Instagram Caption Generator

Podcast Hosting

Groove (Free Account): Replace 17 Apps and Services in Your Business

Groove.ai – All-in-one AI solution

Knife Books

Rakuten (Cash Back for Shopping Purchases)

Transcripts (for podcasts and videos)

Upside App (Cash Back for Gas Purchases)

TubeBuddy (Free Browser Extension and Mobile App for YouTube Creators)

Website Hosting

WordPress Website Hosting

Follow The Knife Junkie

Visit The Knife Junkie website

The Knife Junkie Listener Line — 724-466-4467

Email The Knife Junkie

Follow The Knife Junkie on YouTube

Follow The Knife Junkie on Instagram

Follow The Knife Junkie on Twitter

Join The Knife Junkie Facebook Group

Affiliate Disclosure

In the name of full transparency, please be aware that this website contains affiliate links and any purchases made through such links will result in a small commission for me (at no extra cost for you). If you use these links, I might be rewarded credit or a small commission of the sale. If you don’t want to use these links, no problem. But know that I truly do appreciate your support.